TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 348 of 779

b. Value Rocker Arm Covers.

Refer t o

paragraph

4-14 .

6-30. Cleaning.

a.

Clean cylinder and associated parts, and

remove heavy carbon deposits from combustion

chamber with a scraper or blunt tool which will

not nick or scratch the surface, Remove only the

heavy carbon deposits. Surface need not be

cleaned to a mirror finish.

b.

Clean carbon from fuel injector nozzle seat

using nozzle carbon cutter - 4910-795-7958 as

shown in figure 6-50.

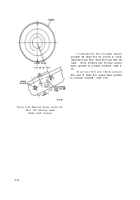

Figure 6-50. Clean ing carbon deposits from

fuel injector nozzle seal using nozzle carbon

cutter - 4910-795-7958.

c.

Soak cylinder in carbon removing com-

pound to remove carbon and other foreig n

material from dome, valve ports, and the area

between the top of the barrel and the head

casting.

6-31. Inspection

a. Valve Guides.

Inspect valve guides (14 and

37, fig. B-4), for cracks, galling, erosion, or

scuffing. Check guides for secure fit in cylinder.

Check guides against limits specified in the

overhaul standards (table 6-15).

Note.

Do not remove valve guides unless

replacement is necessary.

b. Valve Seat Inserts.

Check valve seat inserts

for secure fit in the cylinder (41, fig. B-4). In-

serts must have tight fit. Inspect inserts for

burned or pitted surfaces. Check valve sea t

contact by lightly bluing face of insert with

Prussian blue - 8010-247-8706 and placing a

new valve into position on valve insert. Rotate

valve one-half turn on insert and check valve seat

for Prussian blue contact. Valve seat must show

perfect contact, as indicated by Prussian blue

transfer, to qualify as a serviceable insert. Inserts

that do not show perfect contact must be marked

for repair.

If inserts are cracked, loose, or

damaged beyond repair, the cylinder must be

replaced.

If valve seat inserts can be made

serviceable by grinding; repair as outlined in-

paragraph 6-33a(2). Check the inserts against

limits specified in overhaul standards (table 6-

15).

c. Cylinder.

Two types of cylinders have been

used on the ADVS-1790 series engines. The

latest type cylinder has a wall thickness in-

creased by 0.030 inch to provide greater

strength. These cylinders can be identified by a

machined groove

on the cylinder mounting

flange periphery, refer to figure 6-51.

6-54

Back to Top