TM-9-2815-213-34 - Page 102 of 192

*TM 9-2815-213-34

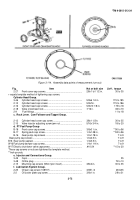

Fig.

Item

Nut or bolt size

Lb-ft.

torque

B-9

Oil pan drain plug .

..................................................................

1 in.

dia.

60 to 70

B-10

Oil pump cover cap screws.

...................................................

3/8x7/8in.

29 to 31

g.

Cooling System Group.

2-4

Fan

hub marsden

nut.

..........................................................

1 ¼ in.

dia.

400 to 500

2-7

Water pump pulley adjustable cap screws.

............................

1/4x1 ¼ in.

8 to 10

2-10

Water header cover plates.

....................................................

3/8x1 in.

29 to 31

h.

Intake and Exhaust System Group.

2-1

Exhaust manifold.

...................................................................

3/8x1 1/4 in.

29 to 31

2-8

Intake manifold.

......................................................................

3/8x 1 1/4 in.

29 to 31

B-12

Preheater nozzle .

...................................................................

15 to 20

B-19

Air inlet adapter cap screws.

..................................................

5/16x1 ¾ in.

17

i.

Air Compressor Group.

2-10

Air compressor support cap screws.

......................................

3/8x1 ¼ in.

29 to 31

Air compressor mounting cap screws.

...................................

3/8x3¼.

in.

29 to 31

j.

Engine Mounting and Adaption Group.

3-22

Flywheel cap screws (140567).

..............................................

5/8x1.5 in.

200 to 205

2-22

Crankshaft adapter (140566) .

................................................

5/8x 27/64 in.

200 to 205

2-28

Flywheel/gear housing cap screws .

.......................................

3/8x2 1/2 in.

28 to 86

NOTE

Always use the specific specifications of the manufacturer listed

above when assembling the engine and its components.

The

torque values given are based on the use of clean,

dry threads.

Reduce torque 10 percent when threads are lubricated with

engine oil.

Reduce by 20 percent if new plated bolts are used.

Back to Top