TM-9-2815-220-24 - Page 72 of 1563

TM 9-2815-220-24

THEORY OF OPERATION

0004 00

ENGINE COMPONENTS (Continued)

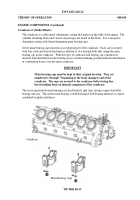

Connecting Rod, Piston, and Piston Pin:

Connecting Rod - The rod connects the piston to the crankshaft.

The connecting rod is the

means by which the reciprocating motion of the piston is changed to rotating motion at the

crankshaft.

The connecting rod assemblies are tapered, I-beam section steel forgings.

A

bronze-lined, steel-backed, split, bushing-type bearing is pressed into the piston pin end of the

rod.

Replaceable precision connecting rod bearings are steel-backed, split type, having

copper-lead alloy bearing surfaces.

Piston - The piston is a cylindrical part closed at one end, connected to the crankshaft by the

connecting rod and traversing a portion of the cylinder bore.

The force of the expanding gases

in the cylinder is exerted against the closed end of the piston, causing the connecting rod to

move the crankshaft.

The pistons are aluminum castings, cam-ground and tapered to provide

an accurate fit in the cylinders at operating temperatures.

The piston dome is machined to the

shape of a conical section so that it tapers into the open-type combustion chamber.

Each

piston is fitted with four rings. The top ring groove is composed of a steel insert, which is an

integral part of the piston.

The three remaining ring grooves are machined into the aluminum

piston.

The upper three rings are compression rings, and the bottom ring is an oil control ring.

Piston Pin - The heavy walled, tubular steel piston pins are full floating in the piston and the

connecting rod.

Retaining rings retain the piston pin in the piston, one at each end of the

piston pin.

WP 0004 00-10

Back to Top