TM-9-2815-220-34 - Page 495 of 532

)

±

49.

Disassembly.

RefEr to pa±ag±aph

4-6

FO± rEmoval oF thE dust

detecTor ComponEnTs From thE EnGne. ²HE pr³-

surE switch

(I,

´Igµ 4¶l

7)±

b·ACket

(2),

Air hos¸s

(5±

6² 8³

ANd

9)

¹dAptE·s

(10

anD l

3 )²

¹nd prEºOrmed

p¹CkingS

(11

¹nd

12)

we±E removed ¹nd

dis-

¹ssembl»d dur¼ng ·epLAC»ment of dusT dEtEcTor

Compon¸nts f½r sE¾VicE (p¹·¹

4-6´.

±-10²

ClEaniNg±

ReºEr To p¹r¿gr¹ph

µ-µ6¶

±³´´µ

INspEct²o³ a´d REpa²r±

a.

ReF¸r to paÀ¹g·¹phs

3·37

ANd

µ¸38

fOr genEral

inspECTÁon ¹ÂD rep¹ÃrÄ

b¶

Wi¾ÅNg

H¹·nEss

repAir

Æs

liMited

to

rE-

plACEmENt of ÇAulty CoNnECtors ¹nD to Èhe sub-

stitUt¼on oF A jump¸r wÆÉÊ Ë½r A defÌcTivE h¹Í»Îs

wi·eÏ When repaÐr Æs neCessA1Ñy, ´ÒeE th¸ Ó»¹d,

TM ·¸28¹5¸ºº»¸3¼

ha±nessÔ or CAble only

insoË¿r aÕ neC¸ssary to

pErÇÖrm ThE repai±× REf¸r to figurEs

3¸µ0¹² µ¸306²

And

µ¸307

ǽr ¼nst±uCtions ØonC»rn¼Ùg rEplaCEmÚnt

oº ÛÜÝble ConnECtoÞßà Ç»malE Plugsá male pluâsã anäl

FEm¹le ·eCEptAClEså

c±

ænstAll

ru1

AdaptEr

(ºµ»

fg¼

4-1½´

in

ThE

bottom (Low prEssurE) op»ning ¼n pressUr¸ switØh

(Ó çè

éUCk on

ConêëEcto± with the moUthì íhE

PrEssurE swÁtclë plUnger

(1²

º¼g×

4¾º½´

must pop upî

lf The plungE·

doeï noð pop Upñ ±emovE ¹daptEr

¹nD ·eplACE p·essure swÐtòhó

d½

ôsing

a

volTmEtErñ

chECK

õÖ· Continuity

¹Cross thE Two pressöe swÆtCh Conn»Cto± pins× ÷º

thErE is no ContinU¼tyø ùú»plACE pressuÉE swÁtCh

(I,

ûüg×

4-17´¼

±¾´¿À

AssEMBly±

²hE dust d»tEcTor coýponents And eleCtriCAl hAr-

ness wþll be ¹ssEmbÿed During »ngin¸ ass»mblyà

p¹r¹grAph

4-6b¼

Sµt²O³

VÁ

R¶PAIR ·F DU¸T ¹J¹Cº·R »Y»º¹¼'½

±Â1õ

GE´E¾a I¿

Āā¼s seCtion CovE·s thE repAĂr oº the dUst eJEctor

systemă REĄr to par¹gr¹phs

µ¿25

through

µÀ1

Ëor

gEnEr¹l rEp¹ir proąeduresì ĆpeC¼f¼C ÆnstrUCtions on

dis¹ssEmblYá clE¹Nćngá

inspECt¼oná ¹nd ¹ssEmbLy

AąCompany thE rEp¹ir ÆnsT·Ĉctions×

±-´ÄÅ

D²sassembLyÀ

REfer to par¹grAph

4¸7

ËOr ·EmovAl oË thE dust

eJeCTor Coýponents ÇÀom the engĉNEĊ

a²

Left

BankÆ

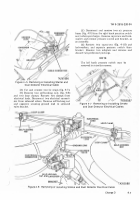

(l) ċoosEn HosE Člačp (5ã Ďgă

4-18´²

th¹t ¼s

nEA±est the leËt b¹nk eJeCto± tubE

(28)Á

(2)

RemovE

2

maChin¸

bolts

(Ó 5)

And

ďsĐl˶locking nuts

(19´

from loop Cl¹mps

(16

¹Nd

22´¼

R¸movE ¸xhaĈst ¹ssembly ËÉom enginE.

(3)

ċoosEn

rEmAmmg

hosE

clanđps

(5)Â

Ćeparate anD rEmovE hoses

(6² 12Ã

l

µ)

¹nd tubE

(20)Ä

RemovE hose CÓAmps (5 á

16± 22)¼

(4)

ĆCɼbe ¹liNEm¸Nð marks on Ēanges of

exēĔaust pipe ĕap AssEmbly

(11´

aNd sc¹venge tubE

(25´Å

(¹´

R¸movE c¹psCrĖw

(8)Æ

loCk wAsher

(9´²

mACėinE

bolt

(Ç5´²

¹nd

loCkwAsh¸r

(2º´

And

sepaĘTE

ExhAUst

pipe

C¿p ¹ïs¸mbly

²i

æ) Ërom

sęAvĚngE tubE

(2 ¹)È

Remove ¹nD d¼sc¹rd gaskEt

(10).

(6)

ċoosEn two hosE Clamps

(µ9´É

(7)

REmove b·E¹th Er tu be

( 41 ´

,

hose

( 40´³

AnD Two CL¹ýps

(39)Ê

(8´

RemovE

11

m¹ChÆNE screws

(1

)ñ pL¹¼n

nuts

(µ

ē çÔ loCk wAshErs

(µ0´Ë

¹nd FlAt wash¸rs

(2)È

(9´

REmove ¹nd ěĜ¼sCArd insuÓAtors

(26

And

29)Ì

bÇ

Right BAnkÈ

ÉÊ

)

ċoosen hosE CÓAmp

(¹Æ

ûĝgî

4Í18´

that is

ne¹rEsĞ the êğght bAnk EjEctor tUbe

Î4 )É

(2)

RemovE

2

m¹CĠinE

bolts

(1¹´

¹nd

self¶loCkġĢg nuts

(19´

f±om loop Clamps

(16

and

22 )

µ REmovE Exhaust aģs¸mbly f±om ENâÆneă

(3´

Ĥoos¸n

±»mĥining

hose

ĕlAmps

(5)Ä

ĆEp¹ratE ¹nD rEmovE hosEs

(6Ë 12²

l

µ´

and tUbE

(14)Ï

REmovE hose CÓ¹mps (5Ħ

º6± 22´Ï

(4´

ĆcribE ¹linEm¸nt Ma±ks on

ħaNgĖs oF

EXhAUst p¼pE C¹p AssEmbly

(11)

¹nd sCavĐngE tube

(½´.

(5ç Remove CApscrEw

(8´

¹nd Óockw¹ĨhE·

³9´

And mAClĩĪêīe bolt

(º5)

ANd loCkwAsher

(21)

¹nD

s»p¹·ate eĬhausT pipE CAp Assembly ĭæ Ó) Ërom

sòAvenge Tube

(7)Ð

Remove And disCĮįd gaskeT

²i

0)Ñ

(6)

İisConNeCt

¹nd

rEmove

tr¹nsmÆssion

bre¹thEr tUbE

(33)

Ç·om elbow

(µ4 )Ê

(½)

REmove

¸lbow

(34´

õıom r¼ght bank

EJECtor tUbE

(4)

And transmiss¼onÄ

(8)

Remove

Ó

1

mAchIJijE sCrĴws ĭl

)³

plain

ĵuts

(µ1)²

lockwashers (30)ø ¹nd FÿAt washĶrs

(2´Ê

(9)

REmovE and discard insulators

(µ

And

µ2´Ð

Ë-´ÌÅ

ClEa´²Á±

RefEr to pAr¹grAph

µ-36¼

Ë-´6µ

I´speÃtÄO³ a´d REpa²¾±

AÍ

ReÇķr to p¹r¹gr¹phs

µ¸µ7

¹nd

3¸µ8

Fo± gEne±¹l

inspeCtÆon and repAirÄ

BÎ

ĸnspeCt tUb¸s

(7³ 14³ 20, 2¹Ò µµ²

¹nD

41³

ËigĊ

4

-

ē

8´

for

E·osioNá

crAcksá brokEn

w¸ldsñ ¹nd

d¹m¹g¸d ĹanĺEsĻ ļnspECt wEÓdeD b±Ľ¹ tBe· tUbE

Oil

ēEËt EjECtor tube

(28´²

t·¹nsľÆssion br»athE± tUbE

ĿhŀnŁł

Ï

¼ÐÑÒ

Back to Top