TM-9-2815-225-34-P - Page 320 of 736

TM 9-2815-225-34&P

0036 00

0036 00-4

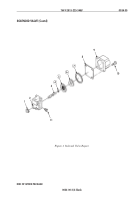

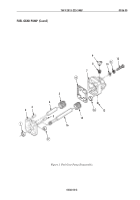

FUEL GEAR PUMP (Contd)

CLEANING AND INSPECTION

1.

For general parts cleaning information, refer to CLEANING, WP 0051 00.

2.

For general parts inspection information, refer to INSPECTION, WP 0051 00.

NOTE

Replace any part that does not pass visual inspection or that is

outside specified wear limits.

The fuel supply elbow contains a check ball. Do not replace

with a standard elbow.

3.

Inspect fuel supply elbow (7), adapter (6), and pipe plug (8) for cracks, chipped or stripped

threads.

4.

Inspect idler shaft (3) and drive shaft (10) for scoring, bends, or stripped teeth.

5.

Using micrometer or equivalent, measure ends of idler shaft (3) outside diameter at center and

end of idler shaft (3). Minimum outside diameter is 0.499 in. (12.70 mm).

6.

Using micrometer or equivalent, measure drive shaft (10) outside diameter at end and center of

drive shaft (10). Minimum outside diameter is 0.499 in. (12.70 mm).

7.

Inspect idler gear (4) and drive gear (9) for chips, cracks, and stripped teeth.

8.

Using micrometer or equivalent, measure idler gear (4) and drive gear (9) length. Idler gear (4)

and drive gear (9) length should be 0.7483–0.7486 in. (19.007–19.014 mm).

9.

Inspect gear body (5) and gear cover (1) for scoring, cracks, or stripped threaded holes.

10.

Using depth micrometer, measure gear body (5) depth. Gear body depth should be 0.7478–0.7481

in. (18.994–19.002 mm).

11.

Using telescoping gauge and micrometer, measure gear body (5) and gear cover (1) shaft bores

inside diameter. Inside diameter should be 0.5011–0.5016 in. (12.728–12.741 mm).

12.

Inspect dowel pins (2) for cracks, chips, or bends.

Back to Top