LO-5-5420-202-13 - Page 2 of 28

LO 5-5420-202-13

Card 2 of 22

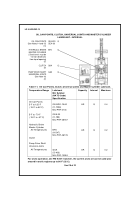

NOTES:

Hard (fixed) time intervals and the related man-hour times are based on normal operation. The

man-hours time specified is the time you need to do all the services prescribed for a particular

interval. Adjust the interval if your lubricants are contaminated or if you are operating the

equipment under adverse conditions, including longer-than-usual operating hours. The interval

may be extended during periods of low activity. If extended, adequate preservation precautions

must be taken.

When checking fluid levels, vehicle must be on level surface.

Oil filters shall be serviced/cleaned/changed when they are known to be contaminated or

clogged, service is recommended by Army Oil Analysis Program (AOAP), or hard time service is

required.

Dispose of used lubricants in accordance with local directives.

Lubricate oil can points that become accessible while performing other lubrication tasks.

Whenever powerplant is removed, remove, clean, and inspect transmission side oil screen

(See note 11).

If operating in 0°F to -65°F (-18°C to -54°C) temperatures without AOAP, quarterly/750 mile

transmission and engine oil changes are required (See note 7).

For arctic operation, see FM 9-207.

For desert operation, see FM 90-3.

Clean all grease fittings before attaching grease gun.

When using grease gun, operate until grease appears around seals or out of relief valve and

check escaping grease for contamination. If contamination is found, notify field maintenance.

If no other treatment is directed, clean and coat unprotected metal surfaces with

Cleaner/Lubricant/Preservative (CLP) (MIL-PRF-63460).

Clean around filler necks/drain plugs/openings before servicing to keep dirt from entering

system.

Back to Top