MWO-9-2320-272-20-4 - Page 4 of 20

MWO 9-2320-272-20-4

e. The items listed below are not included in the Automatic Throttle Kit and must be requisitioned

from stock:

NSN

NOMENCLATURE

CAGEC

PART NO.

QTY.

Plate, Instruction, MWO

19207

10930014

1

Drivescrew

96906

MS21318-20

1

9. SPECIAL TOOLS; TOOL KITS; JIG; TEST, MEASUREMENT, AND DIAGNOSTIC EQUIPMENT (TMDE);

AND FIXTURES REQUIRED.

a. Hand tools necessary to apply MWO are contained in this tool kit:

NOMENCLATURE

NSN

CAGEC

SUPPLY CATALOG

Tool Kit, General Mechanic’s

50980

SC 5180-90-CL-N26

b. Metal drilling equipment necessary to apply MWO is contained in this shop set:

NOMENCLATURE

NSN

CAGEC

SUPPLY CATALOG

Shop Equipment, Machine Shop:

19704

SC 3470-95-CL-A02

Field Maintenance Basic

10. MODIFICATION PROCEDURES.

a. Vehicle Preparation.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

Set parking brake (TM 9-2320-272-10).

Drain air reservoirs (TM 9-2320-272-10).

Remove air cleaner, air cleaner tube hose, air intake pipe, and pump hose assembly

(TM 9-2320-272-20).

Remove accelerator pedal pushrod, return spring, ball joint, and throttle cable from bellcrank

link assembly (TM 9-2320-272-20). Retain washer from accelerator pedal pushrod for use in

task c., step 2.

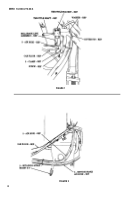

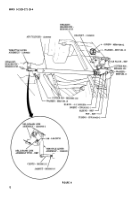

Remove cotter pin, washer, throttle shaft, and bellcrank link assembly from throttle bracket

as shown in figure 1.

Remove screw, two clamps, and air hoses from cab floor as shown in figure 1.

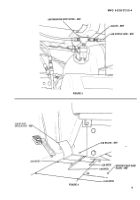

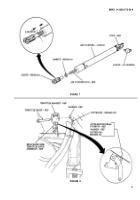

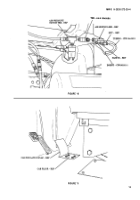

Install two air hoses on service brake air hoses with two MS3367-3-9 retaining straps as

shown in figure 2.

Remove air supply line and elbow from air pressure switch tee as shown in figure 3.

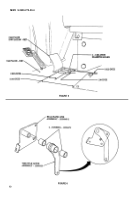

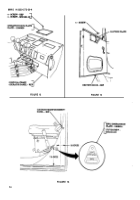

Using driver’s seat base plate as a reference, mark and cut a section of cab floor insulation from

cab floor as shown in figure 4.

Fold back section of cab floor insulation, locate, mark, and drill four 0.281-inch diameter holes

in cab floor as shown in figure 5.

4

Back to Top