MWO-9-2320-272-24-1 - Page 7 of 25

MWO 9-2320-272-24-1

c. Government Verification. All quality assurance procedures performed by installer are subject to

Government verification conducted at varying intervals on an unannounced basis. Verification will consist

of observations, inspections, and tests to determine that the installer’s written quality assurance inspection

plan is properly applied, that all practices, methods, and procedures in effecting the purposes of this MWO

are done to contractual standards, and that the requirements of this MWO, including cited references, are

fully met. Deviation from prescribed or agreed upon procedures will be immediately brought to the attention

of the installer. Failure of the installer to promptly correct noted deficiencies shall be cause for suspension of

acceptance until corrections have been made or until product and service conform to prescribed criteria.

d. In-process Inspection.

During normal assembly operations, inspect cab floor, parking brake lever,

housing, cable, clevis, and associated reused parts ensuring they are rust-free and serviceable. The installer

shall reject any vehicle that has damaged, inoperative, or missing brake system components cited in

Preventive Maintenance Checks and Services (PMCS) found in TM 9-2320-272-10 and TM 9-2320-272-20.

e. Job Inspection. Inspect all installed or replaced parts used during the installation of this MWO for

security of mounting and smooth operation of components. Inspect weld of plate to parking brake lever for

conformity to installation instructions and TM 9-237. Ensure that parking brake cable is adjusted IAW TM

9-2320-272-20. Check for missing, chipped, or cracked paint in the area modified. Prepare and paint as

necessary IAW TM 43-0139. Ensure that air lines are not twisted, pinched, or leaking. Check for loose and

cross-threaded tube fittings and correct as necessary.

14. RECORDING AND REPORTING OF THE MODIFICATION.

NOTE

It is imperative that vehicle serial number is entered in block 2 of DA form 2407

or block 11 of DA form 5504.

a. Records and Report Forms. (Refer to DA PAM 738-750.)

b. Marking Equipment.

(1) After Spring Brake Valve Guard Kit is installed, mark MWO number “9-2320-272-30-1” in the

MWO Applied Block and date applied in Date Block on Instruction Plate NSN 9905-00-858-5682.

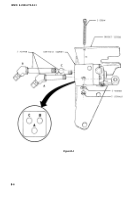

(2) Install instruction plate by drilling one 7/64-inch hole in cab brace and secure with dnvescrew

NSN 5305-00-253-5614 as shown in figure 1.

(3) After drivescrew is installed, flatten or remove protruding excess drivescrew material from

inside of cab brace.

15. MATERIAL CHANGE NUMBER.

This MWO is authorized by Material Change Number 1-88-06-6001.

16. MODIFICATION IDENTIFICATION.

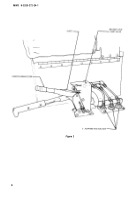

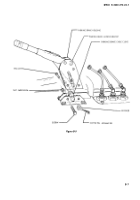

When installed correctly, spring brake valve guard modification to the cab assembly will appear as

shown in figure 2.

6

Back to Top