TB-9-2320-335-13-P - Page 309 of 680

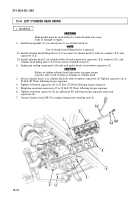

15-5. RIGHT CYLINDER HEAD REPLACEMENT (Cont’d)

NOTE

Use of cylinder head lifting device is optional.

1.1.

Install cylinder head lifting device (1.3) on center of cylinder head (1) with two washers (1.2) and

capscrews (1.1).

1.2.

Install cylinder head (1) on cylinder block (5) and remove two capscrews (1.1), washers (1.2), and

cylinder head lifting device (1.3) from center of cylinder head (1).

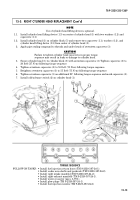

2.

Apply pipe sealing compound to threads and under heads of seventeen capscrews (3).

CAUTION

Failure to tighten cylinder head capscrews in proper torque

sequence may result in leaks or damage to cylinder head.

3.

Secure cylinder head (1) to cylinder block (5) with seventeen capscrews (3). Tighten capscrews (3) to

20 lb-ft (27 N

•

m) following torque sequence.

4.

Tighten seventeen capscrews (3) to 55 lb-ft (75 N

•

m) following torque sequence.

5.

Retighten seventeen capscrews (3) to 55 lb-ft (75 N

•

m) following torque sequence.

6.

Tighten seventeen capscrews (3) an additional 90° following torque sequence and mark capscrews (3).

7.

Install cold-advance switch (2) on cylinder head (1).

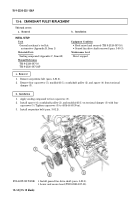

FOLLOW-ON TASKS: • Install fuel injection return hoses (TM 9-2320-387-24-1).

• Install rocker arm shafts and pushrods (TM 9-2320-387-24-2).

• Install right intake manifold (TM 9-2320-387-24-2).

• Install right exhaust manifold (TM 9-2320-387-24-1).

• Install water crossover (para. 3-79.1).

• Install glow plugs (TM 9-2320-387-24-1).

• Install fuel injection nozzles (TM 9-2320-387-24-2).

TORQUE SEQUENCE

TB 9-2320-335-13&P

15-13

1

2

1.1

1.2

1.3

3

6

4

5

1

Back to Top