TM-10-4930-247-13-P - Page 26 of 309

TM 10-4930-247-13&P

1-12.

SYSTEM TECHNICAL PRINCIPLES OF OPERATION - cont.

e.

Open Port Nozzle.

The open port nozzle is used to refuel aircraft having gravity feed, non-pressurized fuel

systems.

The nozzle is inserted into the aircraft fuel tank neck and filled by squeezing the nozzle control lever.

The open port nozzle must be connected to the CCR nozzle for operation.

The pressure regulating feature of the

CCR nozzle limits fuel pressure through the open port nozzle to 15 psi.

f.

(Model HTARS100) Single Point Refueling Nozzle (D1).

The D1 nozzle is used to refuel pressurized aircraft fuel

systems.

Fuel pressure through the D1 nozzle is regulated by the HEMTT tanker.

The D1 nozzle is connected to

the aircraft by mating the nozzle adapter against the aircraft adapter and rotating the nozzle handles until the

connection is firmly locked.

Setting the control lever to the OPEN position unseats an internal poppet and allows

fuel flow through the nozzle.

Mechanical locks prevent the nozzle from being disconnected while the control lever

is set to OPEN.

When the nozzle is disconnected, mechanical locks retain the control lever in the CLOSE

position to prevent accidental fuel spills.

g.

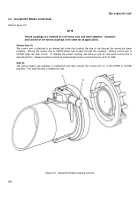

(Model HTARS101) Single Point Refueling Nozzle (D1).

The D1 nozzle is used to refuel pressurized aircraft fuel

systems.

Fuel pressure through the D1 nozzle is controlled by the built-in pressure regulator not to exceed 45 psi

The D1 nozzle is connected to the aircraft by mating the nozzle adapter against the aircraft adapter and rotating

the nozzle handles until the connection is firmly locked.

Setting the control lever to the OPEN position unseats an

internal poppet and allows fuel flow through the nozzle.

Mechanical locks prevent the nozzle from being

disconnected while the control lever is set to OPEN.

When the nozzle is disconnected, mechanical locks retain

the control lever in the CLOSE position to prevent accidental fuel spills.

Clamp and pin type connectors are

attached to the nozzle bonding cable.

h.

Recirculation Nozzle.

The recirculation nozzle is used to circulate fuel from the system fuel hoses back to the

HEMTT tanker.

The nozzle must be connected to the CCR nozzle to operate.

Fuel pressure through the

recirculation nozzle is regulated by the CCR nozzle to 15 psi.

The recirculation nozzle is connected to the tanker

by mating the nozzle adapter against the tanker adapter and rotating the nozzle handles until the connection is

firmly locked.

Setting the control lever to the OPEN position unseats an internal poppet and allows fuel flow

through the nozzle.

Mechanical locks prevent the nozzle from being disconnected while the control lever is set to

OPEN.

When the nozzle is disconnected, mechanical locks retain the control lever in the CLOSE position to

prevent accidental fuel spills.

A ball valve and tube are installed on the nozzle body to allow sampling of the

recirculating fuel.

Change 4

1-9

Back to Top