TM-10-4930-247-13-P - Page 21 of 309

TM 10-4930-247-13&P

1-10.

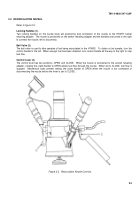

LOCATION AND DESCRIPTION OF MAJOR COMPONENTS - cont.

(1)

(Model HTARS100) Elbows.

Two elbows are supplied with the system and are installed to prevent sharp

bends in the fuel hose.

Each elbow is equipped with drylock couplings.

(Model HTARS101) Elbows.

Two elbows are supplied with the system and are installed to prevent sharp

bends in the fuel hose.

Each elbow is equipped with drylock couplings and manually operated ball valves

to control fuel flow through the elbow.

Valves must be set to CLOSE position before connecting or

disconnecting couplings.

Valves are set to OPEN position during operation.

(2)

2-Inch Hose Assemblies.

Ten 2-inch hose assemblies are used to connect components of the HTARS into

four pumping stations.

Each hose is 50 feet long with drylock couplings at both ends.

Each coupling is

equipped with a manually operated ball valve to control fuel flow through the hose.

Valves must be set to

CLOSE position before connecting or disconnecting couplings.

Valves are set to OPEN position during

operation.

The hose assemblies incorporate internal ground wires that are built into the hose material.

(3)

DELETED.

(4)

(Model HTARS100) Single Point Refueling Nozzle (Type D1).

Four D1 nozzles are supplied with HTARS

for refueling aircraft with pressurized fuel systems.

The D1 nozzles are non-regulating, so fuel pressure

must be controlled by the HEMTT tanker.

The nozzle is internally grounded through the fuel hose.

(Model

HTARS101) Single Point Refueling Nozzle (Type D1).

Four Dl nozzles are supplied with HTARS for

refueling aircraft with pressurized fuel systems.

The D1 nozzle incorporates a pressure regulator designed

to limit maximum fuel pressure to 45 psi.

A coarse screen inside the drylock coupling prevents large

particles of contamination from entering the aircraft fuel system.

The D1 nozzle is internally grounded

through the fuel hose.

(5)

Ground Rods.

Four ground rods are supplied, one for each refueling point.

The ground rods incorporate a

built-in slide hammer to aid installation and removal.

(6)

Closed Circuit Refueling (CCR) Nozzle.

Four CCR nozzles are supplied with the HTARS.

The CCR nozzle

locks onto the aircraft refueling adapter and regulates fuel pressure to the aircraft.

An automatic shutoff

stops fuel flow when the nozzle is disconnected.

Each nozzle is supplied with a ground clamp and plug for

electrical bonding of the nozzle to the aircraft.

The CCR nozzle can be used to refuel aircraft with gravity

feed fuel tanks by connecting the open port nozzle to the fuel discharge coupling.

The CCR nozzle is

required to connect the recirculation nozzle to the HEMTT tanker.

(7)

Port Nozzle.

Four open port nozzles are supplied with the system for refueling gravity-fill type fuel tanks

and containers.

The open port nozzle must be connected to the CCR nozzle for operation.

(8)

Recirculation Nozzle.

One recirculation nozzle is supplied with HTARS.

The recirculation nozzle is

installed between the fuel system supply points and the HEMTT tanker to allow fuel to re-enter the tanker.

The nozzle is equipped with a hand operated ball valve to allow sampling of fuel entering the tanker.

Operation of the recirculation nozzle requires connection of the CCR nozzle.

(9)

Tees.

Three tees are supplied with the system.

Each tee is equipped with drylock couplings and manually

operated ball valves to control fuel flow through the tee.

Valves must be set to CLOSE position before

connecting or disconnecting couplings.

Valves are set to OPEN position during operation.

1-4

Change 4

Back to Top