TM-10-5411-233-13-P - Page 97 of 356

TM 10-5411-233-13&P

CARGO BED COVER (CBC), TYPE III, 2 1/2 T CARGO TRUCK, LMTV, AND LMTV TRAILER

0012 00

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

0012 00-3

THIS SECTION COVERS:

B

efore Operation PMCS Checks and Services

INITIAL SETUP:

CBC in extended and locked position

Maintenance Level

O

perator

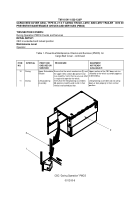

Table 1. Preventive Maintenance Checks and Services (PMCS) for Cargo Bed Cover

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

1

Before

Upper Door

Assembly

Ensure that upper

(1)

door section is properly

engaged. Verify that the three twist knobs

(2)

securing

the upper

(1)

and lower

(3)

door sections are tightened

securely. Verify that hairpin cotter

(4)

in door latch

mechanism

(5)

is installed and undamaged. Verify that

fabric pull strap

(6)

is undamaged. Check for free and

easy operation of Personnel Door

(7)

, latch mechanism

(5),

and door hold-open device

(8)

. Verify that door

latch rods

(18)

do not have excessive wear at the point

where they pass through the rod guides

(19)

.

Personnel door does not open

or close properly.

Door latch mechanism does not

operate properly or hairpin

cotter is missing.

Fabric pull strap is damaged or

missing.

Door hold-open device is

damaged or does not operate

properly.

Ends of door latch roads are

excessively worn.

2

Before

Lower Door

Assembly

Ensure that the lower door section

(3)

is properly

engaged and secured to the upper door section

(1)

.

Lower door section does not

attach securely to the upper

door section.

3

Before

Upper and Lower

Steps

Check for free and easy operation of roof access

folding steps

(9)

. Ensure that the folding steps operate

properly. Check for any cracks or breaks in the folding

steps including loose or missing attaching hardware

(10)

that would create an unsafe condition.

Roof access steps are cracked,

broken, or otherwise damaged.

Roof access step hardware

missing.

4

Before

Lift Rings

Check for free and easy operation of Lift Rings

(11)

.

Ensure that the lift rings operate properly. Check for

any cracks or breaks in the assembly that would create

an unsafe condition. Check for any loose or missing

attaching hardware

(12)

that would create an unsafe

condition.

Lift rings cracked broken or

otherwise damaged.

Lifitng ring hardware missing.

5

Before

Lifting/Locking

Assemblies

Inspect the condition of the lifting/locking assemblies

(13)

. If the CBC is in the height extended mode, ensure

that the lifting/locking assemblies are in their vertical

and locked position.

Lifitng/locking assembly does

not swing into position properly.

Locking mechanism does not

engage properly.

Lifting/locking assembly does

not stow properly.

6

Before

Handhold

Ensure that the roof access step handhold attaching

hardware

(14)

is secure and not missing.

Roof access handhold

attaching hardware missing or

not secure.

7

Before

Ventilation Port

Make sure that the ventilation ports

(15)

are not

blocked. Inspect the air filter

(16)

and clean if

necessary.

Ventilation ports blocked or air

filter dirty.

8

Before

Cabling

Inspect the visible portion of the cabling in the upper

section cable channel. Verify that the winch cabling

(17)

has not been damaged, frayed, or abraded in any

way.

Cable damaged, frayed, or

abraded.

9

Before

Carrier Mounting

Bolts

Ensure that all carrier mounting hardware

(18)

is

securely tightened. Ensure that all vehicle mounting kit

mounting hardware

(19)

is tightened securely.

Carrier hardware missing or not

secure.

Vehicle mounting kit hardware

missing or not secure.

Back to Top