TM-5-2330-378-14-P - Page 132 of 524

TIVI5-2330-378-14&P

4-19. CLEANINGINSTRUCTIONS(continued).

2.

Remove grease and accumulated

deposits with a stiff -bristled brush.

WARNING

Compressed

air used for cleaning

or drying purposes,

or for clearing

restrictions,

should

never

exceed

30 psi (207 kPa). Wear protective

clothing

(gogglestshield,

gloves, etc.) and use caution, to avoid injury to personnel.

3.

Clear out all threaded

holes with compressed

air to remove dirt and cleaning fluids.

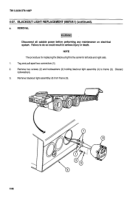

CAUTION

Do not wash oil seals, electrical cables, and flexible hoses with drycleaning

solvent

or mineral spirits. Serious damage or destruction

of material would result.

d.

Oil Seals, Electrical

Cables, and Flexible Hoses.

Wash electrical cables and flexible hoses with solution

of water and detergent (item 4, Appendix F), and wipe dry.

a.

Bearings.

Clean

bearings

in accordance

with TM 9-214.

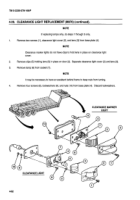

4-20. INSPECTION INSTRUCTIONS.

NOTE

All damaged areas should be marked for repair or replacement.

a.

All components

and parts must be checked carefully to determine if they are serviceable for reuse, can be

repaired,

or must be scrapped.

b.

Inspect drilled and tapped (threaded) holes for the following:

1 .

In or around holes-wear,

distortion, cracks, and any other damage.

2.

Threaded areas-wear, distortion (stretching), and evidence of cross-threading.

C.

Inspect metal lines, flexible lines (hoses), and metal fittings and connectors

for the following:

1 .

Metal lines-sharp

kinks, cracks, bad bends, and dents.

2.

Flexible lines-fraying,

evidence of leakage, and loose metal fittings or connectors.

3.

Metal fittings and connectors-thread

damage and worn or rounded hex heads.

d.

Inspect castings,

forgings, and machined metal parts for the following:

1 .

Machined

surfaces-nicks,

burrs, raised metal, wear, and other damage.

2.

Inner and outer surfaces-breaks

and cracks.

4-44

Back to Top