TM-5-2330-378-14-P - Page 235 of 524

TIVI5-2330-378-14&P

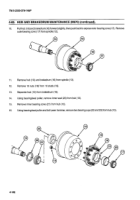

4-68. HUBAND BRAKEDRUMMAINTENANCE(M870)(continued).

b.

CLEANINGANDINSPECTION

WARNING

Drycleaningsolventis toxicandflammable. Alwayswearprotectivegogglesand

glovesanduseonlyinawell-ventilatedarea.Avoidcontactwitheyes,skin,andclothes

andDONOTbreathevapors. DONOTusenearopenflameor excessiveheat.

1.

Thoroughly

clean all metal parts using drycleaning

solvent and a rag.

WARNING

Particles blown by compressed

air are hazardous.

Failure to wear protective goggles

when drying metal parts could cause serious eye injury.

CAUTION

Do not dry bearings

with high-pressure

compressed

air.

Spinning

dry will cause

damage to bearings.

2.

Dry all metal parts with low-pressure

compressed

air.

3.

Checktwo

bearing cones (17and 21) forcracks

and breaks in bearing cage, etching and pitting on rollers, and

evidence

of wear.

If damaged or worn, replace bearing cones.

4.

Inspect two bearing cups (22 and 23) for pits, grooves, and flaking. If pitted, grooved, orflaked,

replace bearing

cups.

NOTE

Replace broken or damaged

studs in groups of three-the

damaged

or broken stud

and the studs on either side.

5.

Inspect 10 studs (19) and nuts (18) for damaged threads or breaks. Replace if threads are damaged or broken.

NOTE

25

Do

steps 6 and 7 only if replacing

10

studs.

6.

Drive studs (19) to be replaced out of hub (10).

7.

Install newstuds(19) in hub (10), being surestud

collars (24) are seated in recessed slot (25).

8.

Inspect brakedrum (16) for pitting or scoring. It

pitted

or scored,

notify

Direct

Support

maintenance.

9.

Inspect spindle (13) for pitting and grooves.

If

pitted

or grooved,

notify

Direct

Support

maintenance.

19

4-147

Back to Top