TM-5-2330-378-14-P - Page 239 of 524

TIVI5-2330-378-14&P

4-69.

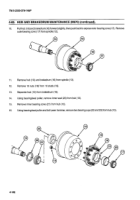

HUBANDBRAKEDRUMMAINTENANCE

(M870A1)(continued).

8.

Remove hub (10) and brakedrum (14) from spindle (16).

9.

Using hammer and drift, remove inner bearing cone (17) and seal (18) from hub (10). If damaged, remove

seal ring If 9) from spindle (16) and discard seal ring.

10.

Remove six capscrews (20) f rom hub (110)and brakedrum (14). Separate hub (10) from brakedrum (14).

if.

Remove inner and outer bearing cups (21 and 22) from hub (10).

b. CLEANING

1. Remove all buildup of dirt from hub and brakedrum components with a soft rag.

WARNING

Drycleaning

solvent is toxic and flammable.

Always wear protective

goggles and

gloves and use only in a well-ventilated

area.

Avoid contact with eyes, skin, and

clothes and DO NOT breathe vapors.

DO NOT use near open flame or excessive heat.

2.

Using a clean, soft rag, thoroughly

clean all parts with drycleaning

solvent.

WARNING

Particles blown by compressed

air are hazardous.

Failure to wear protective goggles

when drying metal parts could cause serious eye injury.

CAUTION

Do not dry bearings with high-pressure

compressed

air. Spinning will cause damage

to bearings.

3.

Dry all metal parts with low-pressure

compressed

air.

C.

INSPECTION

1 .

Inspect flange area and hub (10) for cracks.

Replace hub if damaged.

2.

Check outer and inner bearing cones (15 and 17) for cracks, wear, or pitting on rollers. Replace bearing cones

if damaged.

3.

Inspect innerand outerbearing

cups (21 and 22)forpits,

grooves, orflaking.

Replace bearingcups

if damaged.

4-151

Back to Top