TM-5-2330-378-14-P - Page 241 of 524

TM 5-2330-378-14&P

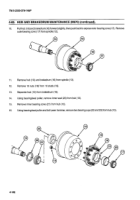

4-69.

HUBANDBRAKEDRUMMAINTENANCE

(M870A1)(continued).

2.

Remove all burrs from hub (10) and thoroughly clean entire wheel cavity.

3.

Using brass drift, install inner and outer bearing cups (21 and 22) in hub (10).

4.

Install hub (10) on brakedrum (14).

5.

Secure hub (10) to brakedrum (14) with six capscrews (20). Torque capscrews to 175 ft-lb (327 Nom). Be

sure indentation in brakedrum (14) is between two spokes in hub (10).

6.

Lay hub (10) and brakedrum (14) hub side down. Thoroughly oil inner bearing cone (17) and place it in inner

bearing cup (21).

7.

Apply a thin coat of sealing compound on outside diameter of seal (18), and position seal (118)in starting

position in hub bore. Place seal inserter and bearing insertion guide on seal with handle in vertical position.

Strike tool with a sharp blow to start seal (18) into bore. Drive seal (18) into bore until completely

seated. Be

sure there is at least

1/32-inch

(8 mm) clearance between inner bearing cone (17) and seal (18).

NOTE

Do steps 8 through 10 only if seal ring was removed.

8.

Thoroughly clean spindle (16) and axle shoulder (24). Remove any burrs on axle shoulder (24) and any

foreign matter in threaded area.

Apply thin coat of sealing compound

to outside diameter of axle shoulder

(24).

9.

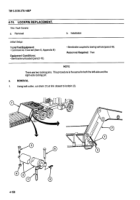

Place seal ring (19), seal inserter, and axle tool head on axle. Tap end of axle tool head to start seal ring (19)

into axle shoulder (24) and drive until axle tool head is against bottom of axle shoulder (24).

10.

Check position of seal ring (19). Edge of ring should be flush with shoulder face. If necessary, place axle

tool head back in position and repeat step 9. Remove any excess sealing compound.

CAUTION

Damaged seal or seal ring will allow lubricant to leak, causing damage to equipment.

If seal and/or seal ring is damaged while installing the hub and brakedrum,

replace It.

it.

Install assembled hub (10) and brakedrum (14) over spindle (16), being careful to align wheel bore with axle.

Do not damage seal ring (19) and seal (18).

NOTE

Support hub and brakedrum assembly until outer bearing cone and spindle nut are

installed.

12.

Install outer bearing cone (15) on hub (10).

13.

Install inner spindle nut (13) on hub (10) with guide pin facing outward. Torque inner spindle nut (13) to 75

ft-lb (101.7 N-m), then rotate braked rum (14) and retorque. Loosen inner spindle nut (113)1/4tum. Installnew

lockring (12) and outer spindle nut (11) on spindle (16). Torque outer spindle nut (11) to 200 ft-lb (271 N-m).

4-153

Back to Top