TM-5-3805-254-14-P-2 - Page 178 of 894

TRUCK SERVICE MANUAL

discharge line.

When the air along with the water and

contaminants enter the air dryer, the velocity or speed of

the air reduces substantially and much of the entrained

liquid drops to the bottom or sump of the air dryer.

The

initial air flow is toward the bottom of the dryer,

but air

flow direction changes 180 degrees at the bottom of the

air dryer dropping some water and oil.

The air now passes through the oil filter which

removes some oil and foreign material but does not

remove water vapor.

At this point, the air remains

saturated with water.

The filtered air and vapors penetrate the desiccant

drying bed and the adsorption process begins.

Water

vapor is removed from the air by the desiccant.

The unsaturated "dry air" passes through the ball

check valve and purge orifice into the purge volume.

From the purge volume air flows through a check valve

and into the first reservoir.

NOTE: The AD-1 Air Dryer does not

incorporate an integral check valve.

The

single check valve in an AD-1 installation

would be located in the line between the

AD-1 outlet port and the first reservoir.

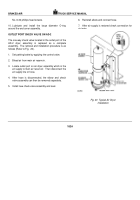

Purge Cycle (Fig.

6)

When desired system pressure is reached the

governor cuts out, pressurizing the unloader cavity of the

compressor which unloads the compressor (non-

compressing cycle).

The line connecting the governor

unloader port to the end cover purge valve port (bottom

of the air dryer) is also pressurized, opening the exhaust

of the purge valve to atmosphere.

With the exhaust of

the purge valve open, contaminants in the discharge line

and dryer sump are purged or forced past the open

exhaust out to atmosphere.

The reverse air flows across the desiccant and starts

the removal process of moisture from the desiccant

surface.

Dry air flowing from the purge volume through

the purge orifice and across the drying bed further dries

the desiccant.

The combination of these reverse flows strips the

water vapor from the desiccant (drying bed).

This

normally takes between 12-15 seconds.

Fig .

6 .

Operational Purge Cycle

The desiccant becomes activated from this cycle and

is now ready for another charge cycle, which occurs

when the compressor returns to the compressing cycle.

It is for this reason the air dryer must be purged for 20

seconds after receiving moisture saturated air for a

maximum of 60 seconds from a 1.2

m2

(12 CFM)

compressor.

MAINTENANCE & CHECKING SERVICEABILITY

Every 37, 000 km (23, 000 miles) or every three

months:

1. Inspect for moisture in the air system by opening

reservoirs, drain cocks or valves and checking

for presence of water.

In areas where more than

approximately a 170 C (300 F) range of

temperature is common, small amounts of water

can accumulate in the air brake system due to

condensation.

The presence of small amounts

of water due to condensation is normal and

should not be considered as an indication that

the dryer is not performing properly.

The desiccant cartridge should be replaced or

rebuilt when it has been determined that the

desiccant is contaminated and does not have

adequate water adsorption capacity.

However,

the following checks should be made before

replacing the desiccant cart

176

BRAKES-AIR

Back to Top