TM-5-3805-254-14-P-2 - Page 179 of 894

BRAKES-AIR

TRUCK SERVICE MANUAL

ridge to ascertain that the water accumulation is not

related to the following listed items:

a. An outside air source has been used to charge

the system.

This air did not pass through the

drying bed.

b. Air usage exceptionally high and not normal for a

highway vehicle.

This may be due to accessory

air demands or some unusual air requirement

that does not allow the compressor to load and

unload (compressing and non-compressing

cycle) in a normal fashion.

Check for high air

system leakage.

c. The air dryer has been installed in a system that

has been previously used without an air dryer.

This type system will be saturated with moisture

and several weeks of operation may be required

to dry it out.

d. Location of the air dryer is too close to the air

compressor.

Refer to "Installation" section.

2.

Check mounting bolts for tightness.

Check all air

and electrical connections.

3.

Check the operation of the integral single check

valve in the AD-2 or the "in-line" check valve used

with AD-1.

Build the air system, to governor cutout

and observe the test air gauge installed in the

supply reservoir.

A rapid loss of pressure could

indicate a failed check valve.

This can be

confirmed by checking at the purge valve exhaust.

NOTE: Purge valve will be open when governor

cut-out pressure is reached.

Allow two minutes

for purge cycle before testing the check valve.

4.

Check for excessive leakage at the purge valve by

coating the exhaust with a soap solution while the

compressor is loaded (compressing air).

5.

Check the operation of the safety valve by pulling the

exposed stem while the compressor is loaded

(compressing air).

There must be an exhaust of air

while the stem is held and the valve should reseat

when the

stem is released.

6.

Check all lines and fittings leading to and from the air

dryer for leakage and integrity.

7.

Check the operation of the heater and thermostat

during cold weather operation.

This can be done by

allowing the end cover assembly to cool below 100 C

(500 F) and feeling the end cover when the ignition is

turned on.

The end cover should be warm to the

touch within a few moments.

Warming should cease

at about 300 C (850 F).

The desiccant change interval may vary;

however, it is generally recommended that the desiccant

be replaced every 12 months (yearly).

If experience has

shown that extended or shortened life has resulted for a

particular installation, then the yearly interval can be

increased or reduced accordingly.

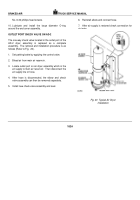

REMOVAL OF DESICCANT CARTRIDGE AD-1 & AD-2

1.

Make certain the vehicle is safely parked.

Block the

wheels if necessary.

2.

Drain the air system completely being sure that the

lines leading into and out of the air dryer are at

atmospheric pressure.

3.

Disconnect the air line from the end cover and mark

location of this port on the dryer.

4.

Disconnect the heater wire.

5.

Loosen the three capscrews on the end cover and

turn the retaining clamps aside (capscrews may be

left finger tight).

6.

Locate the notch in the dryer shell.

While pushing

the end cover up into the dryer, insert the blade of a

screwdriver in the notch and slowly pry out the

retainer ring.

Remove the end cover assembly and

set it aside temporarily.

7.

Using a 3/4" socket wrench, remove the cartridge

and desiccant sealing plate assembly.

NOTE: Be certain the desiccant sealing

plate assembly comes out with the

cartridge.

177

Back to Top