TM-5-3805-254-14-P-2 - Page 315 of 894

TRUCK SERVICE MANUAL

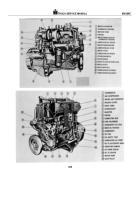

ENGINE

Operating Principles

Engine

Cummins Diesel Cycle

Cummins Diesel Engines have a high compression ratio;

the charge taken into combustion chamber during the

intake stroke consists of air only with no fuel mixture.

Cummins injectors receive low-pressure fuel from the

fuel pump and deliver it into individual combustion

chambers at the proper time, in equal quantity and

atomized condition for burning.

Ignition of fuel is caused

by heat of compressed air in the combustion chamber.

It is easier to understand the function of engine parts if it

is known what happens in the combustion chamber

during each of the four piston strokes of the cycle.

The

four strokes and order in which they occur are:

Intake

Stroke, Compressor Stroke, Power Stroke and Exhaust

Stroke.

In order for the four strokes to function properly, valves

and injectors must act in direct relation to each of the

four strokes of the piston.

The intake valves, exhaust

valves and injectors are camshaft actuated, linked by

tappets or cam followers, push rods, rocker levers and

valve crossheads.

The camshaft is gear driven by the

crankshaft gear, thus rotation of the crankshaft directs

the action of the camshaft which in turn controls the

opening and closing sequence of the valves and the

injection timing (fuel delivery).

Intake Stroke

During intake stroke, the piston travels downward; intake

valves are open, and exhaust valves are closed.

The

downward travel’ of the piston allows air from the

atmosphere to enter the cylinder.

On turbocharged

engines the intake manifold is pressurized as the

turbocharger forces more air into the cylinder through the

intake manifold.

The intake charge consists of air only

with no fuel mixture.

Compression Stroke

At the end of the intake stroke, intake valves close and

piston starts upward on compression stroke.

The

exhaust valves remain closed. At end of compression

stroke, air in combustion chamber has been forced by

piston to occupy a smaller space (depending upon

engine model about one-fourteenth to one-sixteenth as

great in volume) than it occupied at beginning of stroke.

Thus, compression ratio is the direct proportion in the

amount of space the air occupies in the combustion

chamber before and after being compressed.

Compressing air into a small space causes temperature

of that air to rise to a point high enough for ignition of

fuel.

During last part of compression stroke and early part of

power stroke, a small metered charge of fuel is injected

into combustion chamber.

Almost immediately after fuel charge is injected into

combustion chamber, fuel is ignited by the existing hot

compressed air.

Power Stroke

During the beginning of the power stroke, the piston is

pushed downward by the burning and expanding gases;

both intake and exhaust valves are closed.

As more fuel

is added and burns, gases get hotter and expand more

to further force piston downward and thus adds driving

force to crankshaft rotation.

Exhaust Stroke

During exhaust stroke, intake valves are closed, exhaust

valves are open, and piston is on upstroke.

Upward travel of piston forces burned gases out of

combustion chamber through open exhaust valve ports

and into the exhaust manifold.

Proper engine operation depends upon two things first,

compression for ignition; and second, that fuel be

measured and injected into cylinders in proper quantity at

proper time.

Fuel System

The PT fuel system is used exclusively on Cummins

Diesels.

The identifying letters, "PT," are an abbreviation for

"pressure-time." The operation of the Cummins PT Fuel

System is based on the principle that the volume of liquid

flow is proportionate to the fluid pressure, the time

allowed to flow and the passage size through which the

liquid flows.

To apply this simple principle to the

Cummins PT Fuel System, it is necessary to provide:

1.

A fuel pump.

2.

A means of controlling pressure of the fuel being

delivered by the fuel pump to the injectors so individual

cylinders will receive the right amount of fuel for the

power required of the engine.

3.

Fuel passages of the proper size and type so fuel will

be distributed to all injectors and cylinders with equal

pressure under all speed and load conditions.

4.

Injectors to receive low-pressure from the fuel pump

and deliver it into the individual combustion chambers at

the right time, in equal quantities and proper condition to

burn.

311

Back to Top