TM-5-3805-254-14-P-2 - Page 319 of 894

TRUCK SERVICE MANUAL

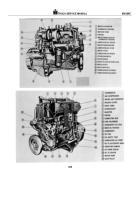

ENGINE

Lubricating oil is drawn from the pan, through a suction

tube, by the lubricating oil pump, Fig.

5-13, then

transferred from the suction cavity by the pump gears

into the pressure cavity.

Lubricating oil passes from the pump into the block, then

across the front of the block by means of an internal oil

passage and enters the cooler support.

Oil is routed out

of the cooler support and into the cooler housing,

passing through the cooler housing.

(The oil cooler is a

counterflow tube-and-shell type heat exchanger, with oil

passing from front to rear through the shell and coolant

water passing from rear to front through the tubes.) Oil

exits the cooler housing and passes into the cooler

cover, then enters the "rifle drilling" at the bottom rear of

the cooler housing and flows forward into the filter head.

Lubricating oil flowing into the filter shell from the filter

head enters outside the filter element and passes

through the element from outside to inside.

Filtered

lubricating oil then re-enters the filter head and flows

through rifle drilling in the bottom of the cooler housing,

then flows forward out of the cooler housing and into the

cooler

support

where

the

flow

divides.

Filtered and cooled lubricating oil re-enters the block

from the cooler support and is transferred internally back

across the front of the block through a drilled oil transfer

passage to the head of the main rifle drilling.

Accessory

drive lubrication is supplied from the transfer passage

out the front of the block and into the gear cover on the

exhaust side of the engine, then across the front of the

engine through a tube in the gear cover.

The flow path

then splits, part being routed to the accessory drive

bushing in the gear cover and the rest being routed to

the air compressor.

Piston-cooling is supplied from the transfer passage

leading to the head of the main rifle drilling.

An

intersecting drilling allows flow to the piston-cooling rifle

which extends from the front to the rear of the block on

the exhaust side of the engine.

Six piston-cooling

nozzles inserted from the outside of the block direct a

spray of lubricating oil from the piston-cooling rifle to the

bottom of each piston.

Lubricating oil entering the main rifle is routed by means

of drilled passages and pipes to the main bearings, rod

bearings, piston pin bushings, camshaft bushings, cam

follower shafts and levers, rocker box shafts and rocker

arms, etc. then returns to the oil pan.

Cooling System

Water is circulated by a centrifugal water pump mounted

either in or on the front of the engine belt driven from the

accessory drive or crankshaft.

Water circulates around wet-type cylinder liners, through

the cylinder heads and around injector sleeves. Injector

sleeves, in which injectors are mounted, are designed for

fast dissipation of heat.

The engine has a thermostat to

control engine operating temperature.

Engine coolant is

cooled by a radiator and fan or a heat exchanger.

The Fleetguard D C A Water Filter is standard on

Cummins Engines.

The filter by-passes a small amount

of coolant from the system via a filtering and treating

element which must be replaced periodically.

Air System

The diesel engine requires hundreds of gallons of air for

every gallon of fuel that burns.

For the engine to operate

efficiently, it must breathe freely, intake and exhaust

systems must not be restricted.

The intake air should always be routed through an air

cleaner.

The cleaner may be mounted on engine or

equipment and may.

be either oil bath, paper element of

composite type depending upon engine application.

Air

is routed from air cleaner directly to intake air manifold or

turbocharger.

Turbocharger

The turbocharger forces additional air into combustion

chambers so engine can burn more fuel and develop

more horsepower than if it were naturally aspirated.

In some cases the turbocharger is used for the engine to

retain efficiency (balanced fuel to air ratio) at altitude

above sea level.

The turbocharger consists of a turbine wheel and.

a

centrifugal blower, or compressor wheel, separately

encased but mounted on and rotating with a common

shaft.

The power to drive turbine wheel - which in turn drives

the compressor - is obtained from energy of engine

exhaust gases.

Rotating speed of the turbine changes

as the energy level of gas changes; therefore, the engine

is supplied with enough air to burn fuel for its load

requirements.

The turbocharger is lubricated and cooled by engine

lubricating oil.

315

Back to Top