TM-5-3805-254-14-P-2 - Page 328 of 894

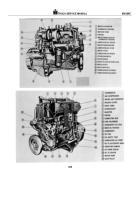

TRUCK SERVICE MANUAL

ENGINE

Note

:

To avoid dropping plunger, do not turn injector upside-

down.

Place injectors in a rack for protection.

Number by

cylinder from which removed.

Cylinder Heads

Compression Release Shaft

Remove shaft lockscrew and copper washer at rear of cylinder

block.

Pull shaft through block from lever end.

Note:

Do not remove stop pin from cylinder block unless

damaged.

Cam Follower Housings

Note

: Do not discard metal spacer used on some engines.

Gasket(s) total thickness varies to space cam follower

housings for establishment of injection timing.

.

Flywheel

1.

Install two (2) 5/8-18 studs in crankshaft flange to

provide support for flywheel during removal.

2.

Install two (2) 1/2-13 capscrews, threaded their entire

length, to act as jackscrew to pull flywheel from crankshaft.

Flywheel Housing

Oil Pan

Note:

Two bolts through oil pan and cylinder block

flange

at flywheel end of engine may be dowel fit.

Remove nuts and

drive out dowel bolts with soft hammer.

Rear Cover And Seal

Gear Case Cover

If gear case cover is equipped with outboard bearing at

camshaft, remove from cover.

Place two (2) guide studs into

capscrew holes to Support cover during removal.

Camshaft And Gear

Note

:

Rotate camshaft while pulling camshaft from engine.

Do not remove gear.

Connecting Rod And Piston Assemblies

1.

Turn engine right-side-up and clean all carbon from

upper inside wall of each cylinder liner and polish with fine

emery cloth.

Do not damage liner finish.

Clean area

thoroughly.

2.

Use care not to damage cylinder liners as connecting

rods are withdrawn.

Check each’ rod and cap as removed to

be sure it is stamped or labeled.

Reassemble each

connecting rod cap to mating rod, tape mating bearing shells

together and label by cylinder.

3.

Remove and discard piston rings, remove snap rings.

4.

To facilitate removal of piston pins, first heat piston in

boiling water; then push pin from piston, using finger pressure

or other suitable method.

Do not drive or otherwise force pin

from piston.

Remove and discard piston rings.

Cylinder Liners

Use ST-1201 Liner Puller Bridge and ST-1202 Liner Puller

Assembly with an impact wrench or rachet to remove cylinder

liners.

Discard "O" rings and crevice seals.

Crankshaft And Main Bearings

1.

Using ST-1178 Main Bearing Cap Puller, loosen main

bearing caps from dowels.

Lift caps and rear thrust rings from

block.

Make sure all bearing caps are marked so they can be

installed in their original locations.

2.

Remove lower main bearing shells from main bearing

caps or crankshaft.

3.

Remove crankshaft using hooks protected by rubber

hose.

Handle crankshaft with care to avoid possible damage

to finished surface.

4.

Remove upper main bearing shells and ring dowels

from cylinder block.

Tape mating halfs of bearing shells

together and identify from position removed.

CLEANING

Steam Cleaning

Steam clean all disassembled units and parts (except those

that might be damaged by steam or-moisture) with a steam jet

and dry with compressed air.

All units such as oil coolers, oil

pan, heat exchanger, etc.

should be cleaned as quickly as

possible to prevent hardening and drying of accumulated

foreign substances.

Glass Bead Cleaning Glass bead cleaning has been proven

most effective for

324

Back to Top