TM-5-3805-254-14-P-2 - Page 371 of 894

TRUCK SERVICE MANUAL

Service Tools (Or Equivalent) Required

ST-195

Plug Gauge

ST-249

Mandrel and Block

3T-970

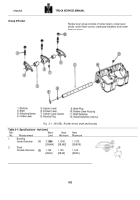

Plug Driving Mandrel

ST-1053

Plug Driving Mandrel

Standard Tools Obtain Locally

Small Bore Gauge

Micrometer (o to 1 inch)

Micrometer (1 to 2 inch)

Feeler Gauge (0.006 inch

[0.15 mm])

CAM FOLLOWERS

DISASSEMBLY AND INSPECTION

1. Remove lockscrews holding shafts in housing

and cup plug by using a sharp pointed chisel.

Using

proper mandrel press both shafts out opposite end

forcing remaining cup plug out of hole.

Mark or tag cam

follower levers for position before removal.

2. Remove cam follower levers from housing.

Clean other parts in solvent.

3. Measure outside diameter of shafts with

micrometers.

If worn smaller than 0.748 inch [19.0 mm]

mark for replacement.

4. Check cam follower shafts around lockscrew

end to make sure grooves are clean, inspect cam

follower housing for

cracks

or

mating

surface

imperfections.

Discard unserviceable parts.

5. Check cam follower bushings for scratches,

pitting or scoring.

Check bushing inside diameter with

micrometers.

If worn larger than 0.7515 inch [19.088

mm] mark for replacement.

6. Check for surface imperfections by magnetic

inspection.

Apply coil magnetization, amperage at 300 to

500 with residual Magnaglo.

7. Inspect edges of cup plug holes in cam follower

housing for sharp edges or nicks.

If damaged, chamfer

entrance of hole to form a slight radius and break sharp

edges to aid installation of cup plug.

8. Cam follower levers have a removable insert (3,

Fig. 4-2).

These must be replaced if scored or extremely

worn.

Check with a new push tube ball or 0.625 inch

[15.88 mm] checking ball and Prussian Blue.

This area

must "blue in" 80% blue or insert must be replaced.

9. Remove cam roll pins (5), roller pins (4) and

rollers (6) from cam follower levers (2).

10. Inspect cam rollers.

Set small bore gauge

0.0002 inch

[0.005 mm] above worn replacement limit listed in Table

4-1.

Use as a "No-Go" gauge in bore to check wear

beyond replacement limits

Check for out-of-round holes.

New dimensions on injector cam rollers are 0.503 to

0.504 inch [12.78 to 12.80 mm].

Worn replacement limit

is 0.505 inch [12.83 mm].

On valve cam rollers new

dimensions are 0.5005 to 0.5015 inch [12.713 to 12.738

mm].

Worn replacement is 0.503 inch [12.78 mm].

If

rollers do not meet these specifications, mark for

replacement.

Back to Top