TM-5-3805-254-14-P-2 - Page 361 of 894

TRUCK SERVICE MANUAL

2. Use a flat mill file to file sleeve flush with top of

cylinder head.

Do not damage head surface.

Remove

burrs from inside diameter of sleeve, clean all cuttings

and filings from water passages.

3. If proper sleeve is not available, heavy wall

copper tubing may be used.

Tubing must provide 0.002

to 0.005 inch [0.05 to 0.13 mm] press fit.

Overall length

should be approximately 1/2 inch [12.70 mm]; inside

diameter must be 7/16 inch [11.11 mm] to allow proper

water flow.

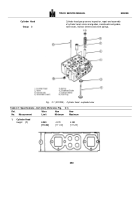

Resurface Cylinder Head

If cylinder head has been scratched, etched or is uneven

at point of contact in gasket sealing area, head may be

milled or surface ground.

1. Use ST-1 133 Valve Seat Extractor, remove all

valve seat inserts.

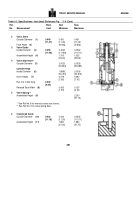

2. After resurfacing check head height, use

micrometer or vernier depth gauge.

Do not remove

more than indicated as worn limit.

See Table 2-1 (1).

3. Rework valve seat insert counterbore, remove

amount of stock equal to that removed during cylinder

head resurfacing.

Replace Valve Guides

1. Drive out guides marked for replacement from

underside of cylinder head.

Install new valve guide with

ST-1217 Mandrel or if valve guide bore in cylinder head

has been damaged, install oversize guides as follows:

a. Using ST-1188 Reamer, ream defective valve

guide bore in head to 0.760 to 0.761 inch [19.30 to 19.33

mm].

Ream through, remove all burrs.

Corner break

should not exceed 0.015 inch [0.38 mm].

b. Using ST-1217 Mandrel, press oversize valve

guide, Part No.

208362, into cylinder head.

Note

: If damaged valve guide bore does not clean up,

use ST-1187 Reamer, Ream 0.765 to 0.766 inch [19.43

to 19.46 mm] and use oversize valve guide, Part No.

208363.

Repeat Steps a and b above.

It may be

necessary to ream valve spring guide hole to 0.768 to

0.773 inch [19.74 to 19.75 mm] to accommodate

oversize valve guides.

2. If proper valve guide mandrel is not available,

press guide into head.

See Table 2-1 (3).

3. Normally valve guide inside diameter does not

require reaming.

Insert valve stem into guide and check

for freedom of movement.

4. If reaming is necessary: Ream valve guide from

bottom side of cylinder head using ST-646 Reamer.

Use

lubricating oil or soluble oil and water solution for proper

finish.

Do not ream valve guide beyond worn limit as

listed in Table 2-1 (3).

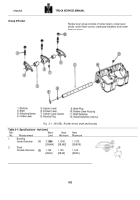

Replace Crosshead Guides

1. Remove crosshead guides marked for

replacement using ST-667 or ST-1134 Dowel Puller.

2. Using ST-633 Crosshead Guide Mandrel, press

new guides into cylinder head.

If mandrel is not

available, press new guides into head to obtain

protrusion as listed in Table 2-1 (6).

3. Oversize crosshead guides may be installed as

follows:

a. Drill guide bore in head to original depth with a

29/64 inch [11.51 mm] drill.

b Lubricate and ream bore with 15/32 inch [11.

mm] reamer.

c. Install oversize guide, Part No.

161527, as per

Step 2 above.

Replace Valve Seat Insert

1. If cylinder head has not been resurfaced, use

ST-1133 Valve Seat Extractor to remove valve seat

inserts that are marked for replacement.

2. Enlarge counterbore to next oversize.

Inserts

are available in standard oversizes as listed in Table 2-1

(8).

Back to Top