TM-5-3805-254-14-P-2 - Page 360 of 894

TRUCK SERVICE MANUAL

Fig.

2-7 (N10231) Minimum valve head rim thickness

low amperage, at 100 to 200 amps, and then inspected

residually with Magnaglo.

A crack at, or near, the weld

would show as a sharp bright fluorescent line.

3.

Valves with only one type of metal can be

inspected in normal way.

Magnetize and inspect in two

directions.

Coil magnetization, use 100 to 300 amps.

Inspect with residual Magnaglo.

Defects found after this

magnetization will be in a transverse direction.

Follow by

headshot magnetization,

at 500 to 700 amps, use

residual Magnaglo.

Defects by this magnetizing method

will be radial.

4. Magnetic indications should be as follows:

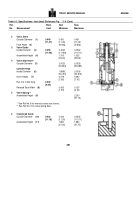

Reference Fig.

2-8.

Fig.

2-8 (N10269) Magnetic indication areas of

maegnaglo

a. No magnetic indication over 1/2 inch [12.70 mm]

in length or more than 5 indications spaced closer than

1/8 inch [3.18 mm] can be accepted in area (1).

b. No visible or magnetic indication acceptable in

area (2).

c. No visible or circumferential magnetic indications

are acceptable in areas (3) and (4).

d. No visible or magnetic indication is acceptable in

area (5).

Note

: "Visible" means indication can be seen by use of

a 3 power magnifying glass after removing magnetic

particle suspension.

5. Demagnetize all acceptable parts.

REBUILDING

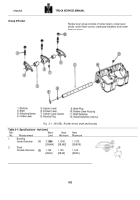

Sleeve Eroded Water Holes

Cylinder head surface around water holes must be free

of any erosion, pits, scratches or blemishes which are

more than 0.003 inch [0.08 mm] deep in the area 1/16 to

5/32 inch [1.59 to 3.97 mm] from edge of water hole.

Use ST-1010 Water Hole Counterboring Tool to enlarge

hole for sleeve.

See Service Tool Instructions.

1. Coat sleeve, Part No.

191078, (1, Fig.

2-9) with

sealant,

align sleeve in top of water passage hole, drive

into position using bushing driver (2) and hammer.

Back to Top