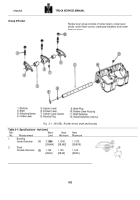

TM-5-3805-254-14-P-2 - Page 363 of 894

TRUCK SERVICE MANUAL

8. Use ST-884 Injector Sleeve Cutter in a drill press

with pilot, using a solid stream of good cutting oil to allow

cutter to cut freely without grabbing, etc.

9. Water test cylinder head.

See Page 2-4.

Grind Valves

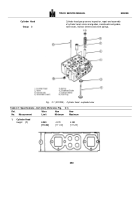

1. Check valve grinder setting by using a new valve

and an indicator gauge:

a. Check valve in valve grinder on guide area of

stem.

Relieved portions on both ends of guide area are

not necessarily concentric to guide area of stem.

b. Indicate on ground face of valve.

c. Turn valve and mark high spot on head of valve.

d. Rechuck valve 180 deg.

from first position.

e. Repeat (b) and (c).

If high spots are same for

both (a) and (d) position, valve is warped.

If high spots

occur in different positions, chuck is out of alignment.

Runout should not exceed 0.001 inch [0.03 mm].

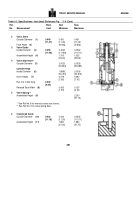

2. Wet-grind valves to an exact 30 dep.

angle from

horizontal.

Check rim thickness as shown in Fig.

2-7.

If

rim is less than 0.105 inch [2.67 mm], valve is not

suitable for reuse.

3. Pencil mark valve face as shown in Fig.

2-12,

position in valve guide against a newly ground valve

seat, rotate valve 10 deg.

A good seat will be indicated if

all pencil marks are broken.

If pencil marks are not

broken, tools need dressing or machine has not been

properly adjusted; final check should be made with a

vacuum tester.

4. Valve seats properly ground with precision

equipment

Back to Top