TM-5-3805-254-14-P-2 - Page 358 of 894

TRUCK SERVICE MANUAL

Fig.

2-3 (V10244) Cylinder head installed In ST-1012

Hydrostatic Tester

may not show water leakage.

Discard head if cracked;

replace leaking sleeves.

2, Open water outlet of test fixture; check for free water

circulation through cylinder head.

If restriction is evident,

remove all pipe plugs and fuse plug; clean water jackets

of salt, lime or sludge.

a. If alkaline cleaners are used in recommended

concentration, immersion times are followed and

temperatures

regulated

according

to

instructions

supplied with each product, no damage will result to

injector sleeve "0" rings.

b. Solvent type cleaners may damage the "O" ring

and should not be used unless the injector sleeves and

"0" rings are all to be replaced.

c. To remove heavy deposits of lime, use circulated

acid-type cleaner.

WARNING

The use of acid is extremely dangerous to workmen and

injurious to machinery.

Always provide a tank of strong

soda water as a neutralizing agent.

3. Clean fuel passage with ST-876 Brush or

equivalent.

Flush passages with solvent to remove

deposits.

Magnetic Crack Detection

As a precautionary measure, check cylinder head for

cracks

using ST-1166 Magnetic Crack Detector in valve and

injector port areas.

Discard head if cracked.

INSPECTION

Valve Seats

1. Check for loose

valve seat.

inserts

by lightly

tapping cylinder head near insert, if valve seat is loose

enough to bounce, mark for replacement.

A slight

looseness found only by tapping when head is cold and

covered with a film of oil is not objectionable.

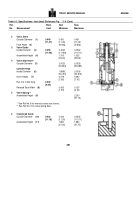

2. If seat area width (2, Fig.

2-4) exceeds 0.125

inch [3.18 mm] at any point and cannot be narrowed

sufficiently (1) during regrind, mark for replacement.

Fig.

2-4 (N10228) Valve seat insert-cross section

Injector Sleeves

Note results of pressure test.

Leaks indicate need for

replacement of injector sleeves.

Visually check sleeves,

which pass pressure test, for scratches on cup seat

area.

If seat area is scratched, mark for replacement.

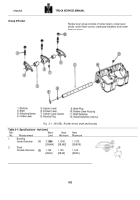

Injector Tip Protrusion

Injector sleeves that have passed the above tests must

further be checked for injector tip protrusion (seat depth)

and seating pattern.

1. Lightly coat injector cup with Prussian Blue,

install injector assembly into sleeve torque to 10 to 12 ft-

lbs [1.4 to 1.7 kg m].

Remove and check seat pattern.

Bluing band must be 0.060 inch [1.52 mm] minimum in

width and located approximately 15/32 inch [11.91 mm]

from

354

ENGINE

Back to Top