TM-5-3805-254-14-P-2 - Page 349 of 894

TRUCK SERVICE MANUAL

ENGINE

7.

Remove unit from cylinder block and sandpaper rough

edges from top and bottom of cut and clean with

compressed

air.

Note

: If tool bit is changed, be sure and reset new tool bit.

Installing Repair Sleeve Into Cylinder Block

1.

Push

sleeve, Part No.

195778, through upper bore and install

sleeve driver when sleeve is positioned in lower bore.

2.

Place sleeve and driver as a unit in position to go into

lower bore, insert driver handle.

Note

: Inside diameter chamfer of sleeve to be toward deck.

3.

Install locator over driver handle and into counterbore.

4.

Tap gently on driver handle until sleeve is located on

starting radius, then drive sleeve into place.

When sleeve is in

correct position, the sleeve drive handle will become free for

removal.

Note

:

This tool is also used when machining the lower bore

entry chamfer.

If erosion has occurred, the chamfer area

may be built up by the use of a plastic steel compound (follow

manufacturers instructions) and resurfaced.

Follow above

instructions using ST-1096-2 Spacer and ST-1096-4

Tool Bit

when remachining chamfer.

ST-1252 Concentricity Gauge

Check the cylinder liner counterbore to lower bore

concentricity as follows:

1.Place gauge flat on top deck of cylinder block with bumper

pins against counterbore inside diameter.

2.

Raise or lower bar to position indicator in area of lower

bore to be checked.

3.

Holding gauge bumper pins firmly against counterbore

inside diameter, zero indicator.

4.

Release pressure, reposition gauge to check indicator

reading.

Rezero indicator if necessary.

5.

Place gauge 180 deg.

from original setting position,

hold bumper pins firmly against counterbore inside diameter,

record indicator reading.

6.

Move gauge 90 deg. and repeat procedure.

Note

:

Indicator readings recorded are two (2) times actual

shift of bore.

(Example: Indicator reading 0.002 inch [0.05

mm].

Actual shift from center of bore 0.001 inch [0.03 mm].

ST-1168 Cylinder Liner Counterbore Salvage Tool

This tool is used to enlarge damaged counterbores for the

installation of salvage sleeve or bores that have been

reworked to maximum depth.

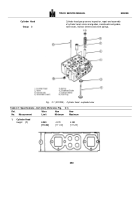

ASSEMBLY OF TOOL

1.Assemble and secure adapter plate (ST-1168-28), (Fig. 1-

15) to main body.

2.

Assemble tool holder (ST-116839) on shaft of main

body (1168) and secure with nut (ST-1168-33) and washer

(ST-1 168-34).

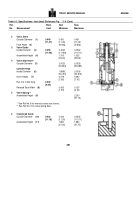

MACHINING THE BLOCK

1.Remove cutting tool from (ST-1 16839) holding plate.

2.

Place boring machine on cylinder block above bore to

be cut and hand start mounting capscrews.

Capscrew

spacers (ST-1168-29 or 40) must be on capscrews.

3.

Lower tool holder into bore by pulling up on orifice

retractor knob (ST-1168-14) while pushing down on set collar

(ST-1 168-12).

4.

Tool holder lower diameter is used to center machine

in counterbore inside diameter.

Push tool holder lower

locating diameter into counterbore and tighten four mounting

capscrews alternately to 25 to 35 ft-lbs [3.5 to 4.1 kg m]

torque.

5.

Retract tool holder by pulling up on orifice retractor

knob (ST-1 168-14).

6.

Loosen setscrew (ST-1168-23) in back end of tool bit

and push adjustable set pin (ST-1168-21) all the way in.

Lock

setscrew.

7.

Adjust micrometer (ST-1168-25) to 6.750 inch [171.45

mm] .

8.

Place tool bit (ST-1168-19) in tool bit gauge and hold

firmly against stop and hardened pad (ST-1168-27).

Loosen

setscrew and allow adjustable set pin to come out against

micrometer spindle.

Lock setscrew.

9.

As a further check, back off thimble on micrometer and

recheck tool bit length again.

10.

Insert tool bit into tool holder and tighten lockscrew

(ST-1168-20).

Tool bit must be held all the way in against tool

holder.

11.

Turn tool holder until tool bit recess is at large opening

in (ST-1168-28) adapter plate.

12.

Place a 0.004 inch [0.10 mm]feeler gauge between

block and tool bit and lower tool bit onto feeler gauge by

345

Back to Top