TM-5-3805-254-14-P-2 - Page 345 of 894

TRUCK SERVICE MANUAL

ENGINE

a.

Hold ring in groove, flush with land and insert 0.006

inch [0.15 mm] feeler gauge.

b.

If gauge enters groove without forcing or disengaging

ring, wear is excessive and piston should not be used.

3.

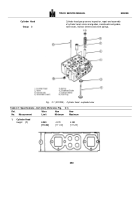

Measure piston skirt diameter with micrometer at right

angle to piston pin bore (A, Fig. 1-11 for barrelground pistons);

measure straight or tapered ground pistons at Point B, 1 inch

[25.4 mm] below ring groove and C, 1 inch [25.4 mm] above

bottom of piston.

Pistons should not be reused if worn more

than 5.483 inch [139.27 mm].

a.

Pin Bore Area

b.

Area Below Ring Groove

c.

Piston Skirt

Fig.

1-11 (N20171) Piston check points.

4.

Pistons should be checked at temperature of 70 to 90

deg. F [21 to 32 deg. C].

After measuring piston and

comparing

with

liner

inside diameter,

piston-to-liner

clearance may be computed if desired.

5.

Piston pin bore checked at 70 deg.

F [21.1 deg. C]

should fall within limits shown in Table 1-1; add 0.0005 inch

[0.013 mm] per 10 deg. F [-12 deg. C] up to 90 deg. F [32 deg.

C] .

6.

Check piston pin outside diameter with micrometer.

Pins should not be reused if out-of-round more than 0.001 inch

[0.03 mm] or worn smaller than indicated in Table 1-1 (13).

Reboring of piston pin bores and use of oversize pins is not

practical because the misalignment that results from such

practice will cause seizure of piston or failure of connecting rod

bearings.

Piston-To-Connecting Rod Assembly

1.

Pistons are machined to a very close weight tolerance;

therefore, as long as the same part number piston is used

throughout the engine, weight does not affect engine

operation.

2.

Be sure rod and cap are stamped with cylinder number

from which removed before disassembly to prevent mixing

parts.

3.

Install one piston pin snap ring in groove of piston pin

bore.

4.

Heat aluminum pistons in boiling water or in an oven at

or below 210 deg. F [98.9 deg. C] and install pin through

piston and connecting rod pin bores before piston cools; at 70

deg. F [21 deg. C] the pin fit is 0.0001 to -0.0003 inch [0.003 to

-0.008 mm] which prevents pin assembly unless piston is

heated, Secure pin with second snap ring in groove at

opposite end of pin bore.

CAUTION

Never drive piston pin in pistons.

Driving may cause

distortion of piston, causing piston seizure in cylinder

liner.

REAR COVER

The rear cover is a unit subject to replacement of seals only.

Damaged housings require replacement by a new assembly or

installation of a "Heli-Coil" for stripped threads; these are only

items of repair.

Alignment during engine assembly is the biggest factor for

proper performance of the rear cover unit.

See Group 14.

CAMSHAFT

INSPECTION

Check

camshaft

bushing

journals

with

micrometers.

Replace camshaft if journals are worn beyond limits given in

Table 1-1 (15).

Replace camshafts that have scuffed, scored, or cracked

injector or valve lobes.

Check by magnetic inspection for

possible cracks.

Cummins Engine Company, Inc.

does

not

recommend

regrinding of camshaft lobes.

Camshaft Support

If cast iron support is used, inspect bushing in support;

remove if damaged or worn smaller than 1. inch [34.80 mm];

press in new bushing flush with inner bore.

New dimensions

are 1.3725 to 1.3755 inch [34.86 to 34.93 mm].

Replace

aluminum support.

Thrust Bearing

Inspect thrust bearing for flaking, burrs, distortion and

341

Back to Top