TM-5-3805-254-14-P-2 - Page 347 of 894

TRUCK SERVICE MANUAL

ENGINE

INSTRUCTIONS FOR USE OF SERVICE TOOLS

ST-1010 Water Hole Counterboring Tool

See Service Tool Instructions, Cylinder Heads, Group 2.

ST-1059 Cylinder Liner Counterboring Tool

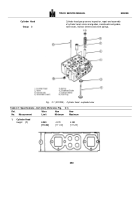

ST-1064 and ST-1065 Service Tools are used in this

operation.

Assemble tools as follows:

1.

Install ST-1059 driver (1), Fig.

1-13, onto ST-1064

adapter (2) with capscrews (4).

2.

Install ST-1065 Tool Holder (3) onto driver unit (1).

Fasten holder onto drive unit with capscrew (5).

1.

Drive of ST-1059

6.

Handle

2.

Adapter of ST-1064

7.

Plunger

3.

Tool Holder of ST-1065

8.

Locking Screw

4.

Capscrew of ST-1064

9.

Adjusting Nut

5.

Capscrew

10.

Capscrew

and

Washer

Fig. 1-13, (V40156).

ST-1059 Counterbore Tool

PRESETTING TOOL BIT

1.

Loosen thumb screw and push adjusting pin back into

housing.

Tighten thumb screw.

2.

Place tool bit setting gauge onto tool holder with dowel

pins, engaging smaller diameter of tool holder and holding

locating surfaces of housing against flat surface of tool holder.

3.

While holding tool bit setting gauge in the above

position, loosen thumb screw allowing adjusting pin to engage

larger diameter of tool holder.

Tighten thumb screw.

4.

Install tool bit into tool holder.

Set point of tool bit

below larger diameter of tool holder and tighten one setscrew.

5.

Place tool bit setting gauge with dowel pins engaging

smaller diameter of tool holder, holding locating surfaces of

housing against flat surface of tool holder.

6.

Position adjusting pin over point of tool bit.

Loosen

setscrews allowing tool bit point to rest against locating point

of adjusting pin.

Tighten setscrews.

INSTALLATION AND OPERATION

1.

Pull out on handle (6) until plunger (7) will hold tool

holder (3) in the up position.

Place unit on cylinder block with

hold-down holes matching in cylinder block.

2.

Hold onto handle (6) and pull out on plunger (7).

Slowly lower tool holder into counterbore.

Engaging larger

diameter of holder allow tool bit to rest on counterbore ledge.

3.

Loosen locking screw (8) and rotate adjusting nut (9)

in clockwise direction until tool bit clears counterbore ledge.

Tighten locking screw.

4.

Assemble hold-down capscrews and washers (10)

through adapter plate into cylinder block finger tight, then

torque to 50 to 75 ft-lbs (6.9 to 10.4 kg m].

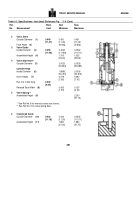

Note

:

Tool holder must rotate freely.

5.

To measure depth of counterbore:

a.

Install depth gauge into gauging hole of adapter plate.

Loosen capscrew and push down on dial indicator to end of

travel.

b.

Pull dial indicator 0.010 to 0.020 inch [0.25 to 0.51

mm] off bottom.

(End of travel.) Tighten capscrew.

c.

Set dial indicator to zero.

d.

Rotate tool holder until red indicator line matches red

line on adapter plate.

e.

Place depth gauge on four counterbore measuring

holes.

The average of the four readings will be the present

depth of counterbore.

See Table 1-1 (2) for counterbore

depth.

6.

To operate counterboring tool:

a.

Loosen locking screw.

Rotate adjusting nut in

counterclockwise direction until tool bit is resting on lowest part

of counterbore ledge and there is clearance between housing

and adjusting-nut.

Note

:

The distance between housing and adjusting nut equals

amount of material that will be removed from counterbore

ledge.

343

Back to Top