TM-5-3805-254-14-P-2 - Page 352 of 894

TRUCK SERVICE MANUAL

ENGINE

(ST-1177-16), Fig. 1-16, through centering rings rotating

slowly.

Bar should spin free.

Slide bar out one end until

appropriate checking ring can be installed in bar.

Oil outside

diameter of checking ring.

5.

Using light finger pressure against checking ring (ST-

1177-13) on both sides of bar, push checking ring through

each bore.

Bar must be turned during this check.

a.

Check bore for burrs if checking ring will not pass

through bore.

b.

A 0.003 inch [0.08 mm] feeler gauge (not over 1/2 inch

[12.70 mm] wide) can be used in detecting irregularities in the

bore.

c.

Attempt to insert feeler gauge between bore and bar or

slip ring as used on ST-1177 Boring Tool.

Run gauge

completely around bar or slip ring on each side of bore.

Evaluate as follows:

(1) Gauge does not enter at any point, bar rotates freely std.

bore.

(2) Gauge enters on one side and not on opposite slight

misalignment.

No problem if bar rotates freely.

(3) Gauge loose oversize bore.

(4) Gauge enters on front and not on rear of bore tapered

bore.

6.

Mark bores to be salvaged.

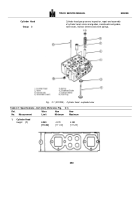

ASSEMBLING MICROMETER TOOL BIT

SETTING GAUGE

AND TOOL BIT

1.

Place micrometer base shaft (ST-1177-46) through

bore of micrometer bracket (ST-1177-45) and thread into

micrometer base (ST-1177-44).

Tighten securely.

2.

Tighten the socket head screw (ST-1177-29) in the

micrometer .bracket until the bracket is tight on the micrometer

base shaft; micrometer hole in micrometer bracket must be in

alignment with cutting tool hole in micrometer base shaft.

3.

Install centering ring (ST-1177-39) over micrometer

base shaft and micrometer (ST-1177-43) in micrometer

bracket:

a.

Adjust micrometer thimble to value stamped on

centering ring.

b.

Hold micrometer spindle against centering ring and

tighten socket head screw in micrometer bracket.

Check to

see that micrometer spindle turns free.

4.

Remove centering ring and install appropriate cutter

holder over micrometer shaft.

5.

Align tool bit hole in cutter holder with hole through

micrometer base shaft and tighten cutter holder socket head

screws.

Scribed lines are used on the base shaft and cutter

holder for this purpose.

Keep even gaps between two halves

of cutter holder.

6.

Insert appropriate cutting bit in tool holder.

Tool must

be short enough so it does not extend into the bore of the tool

holder.

When adjusting micrometer or tool cutter, be careful to

"just contact" tool to prevent damage.

7.

With cutter key (ST-1177-49) adjust tool bit against

micrometer spindle and tighten tool bit retaining screw in cutter

holder, back off micrometer and check tool bit setting.

Note

:

Do not tighten micrometer spindle against tool bit point

or carbide may be chipped.

Do not sweep micrometer spindle

across carbide cutter for it will chip cutting edge.

8.

Back off micrometer and remove cutter holder from

micrometer base shaft.

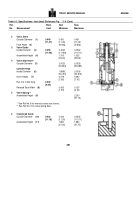

CUTTING BORES

1.

Install bore feed assembly (ST-1177-17) in one end of

boring bar and tighten socket head screw (ST-1177-32).

2.

Install torsion bar (ST-1177-33), threaded end first,

through bore feed assembly, (ST-1177-17) start threads into

end hole of torsion bracket (ST-1 177-34).

The flats on bar

can be used to secure it to bracket.

3.

Locate tapped hole in end of block and secure torsion

bracket to block with a suitable capscrew and washer.

4.

Pull out on plastic knob of feed assembly until pin is

free of slot and turn one-fourth (1/4) turn, then pull complete

feed assembly back all the way to the knob and tighten wing

setscrew in feed assembly to secure on torsion bar.

5.

Install square head set bolt in second threaded hole of

torsion bracket end and tighten snug against cylinder block to

stabilize torsion assembly.

6.

Turn plastic knob on drive assembly one-fourth (1/4)

turn until pin seats in groove.

7.

Install adapter (ST-1177-31) in other end of boring bar

with the 1/2 inch square drive out.

Lock with socket head

setscrew.

8.

Lock swivel joint (ST-1177-27) in a 1/2 inch drill chuck.

These instructions assume use of a right hand rotation drill.

9.

Install tool bit holder on boring bar, next to journal to

be cut.

When operating, boring bar will feed toward feed

assembly.

Make sure tool bit cutting edge is turned in

direction of drill rotation.

10.

With swivel joint on boring bar adapter, bore the

journal.

Keep boring bar well lubricated during all boring

operations.

348

Back to Top