TM-5-3805-254-14-P-2 - Page 348 of 894

TRUCK SERVICE MANUAL

ENGINE

b.

To set the depth of cut, place a feeler gauge of

required thickness between adjusting nut and top of housing.

For example: if 0.005 inch [0.13 mm] of material is to be

removed from counterbore ledge, use 0.005 inch [0.13 mm]

feeler gauge.

Make sure there is no grease or dirt between

adjusting nut and top of housing.

c.

Rotate adjusting nut until feeler gauge is just held

between adjusting nut and top of housing.

Tighten locking

screw.

Remove feeler gauge.

d.

Hold down on handle applying more pressure on tool

bit side and rotate handle in a clockwise direction until unit

turns freely and is bottomed out between adjusting nut and top

of housing.

e.

Measure depth of counterbore as described in Step 5.

ST-1081 Boring Tool (Lower Cylinder Liner Bore)

ST-1064, ST-1081, ST-1081-52 and ST-1084 Service Tools

are also used in this operation.

Assemble boring tool as

follows:

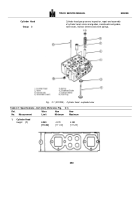

1. Drill Motor

8.

Bore Adapter

2. Drive Gear

9.

Tool Holder

3. Torque Reaction Bar

10.

Capscrew

4. Adapter Plate

11.

Capscrew

5. Retaining Nut

12.

Drive Adapter

6. Retaining Nut Handle

13.

Upper Bearing

7. Boring Tool

Fig. 1-14, (V40153), ST-1081 Tool Bit installed in blockST-

1081 Tool Bit installed in block

1.

Install ST-1084 Bore Adapter (8, Fig.

1-14) onto ST-

1081 Boring Tool.

2.

Install ST-1064 Adapter Plate (4) onto boring tool with

3/4 inch recess toward bore adapter.

3.

Engage retaining nut (5) onto boring tool and tighten

retaining nut until boring tool, bore adapter and adapter plate

are secure.

4.

Install ST-1081-52 Tool Holder (9) into boring tool (7)

and tighten in position with capscrews (10).

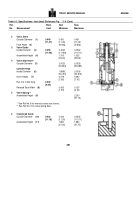

PRESETTING TOOL BIT

1.

Loosen two setscrews.

Install ST-1081-55 Tool Bit

into tool holder, being sure that spring is in place.

2.

Push in on tool bit until it bottoms on spring.

Lock one

setscrew.

3.

Place tool holder into setting gauge and fasten in place

with capscrew finger tight and position point of tool bit so it will

engage setting nib.

Note

:

Proper nib will be indicated by stamped letters or

numerals for particular engine.

4.

Loosen setscrews allowing point of tool bit to engage

setting nib, then tighten against bit.

5.

Remove tool holder and bit from setting gauge.

Install

in boring tool.

INSTALLATION AND OPERATION

1.

Install assembled boring tool into cylinder block,

allowing bore adapter (8) to engage counterbore and holes in

adapter plate to match holes in cylinder block.

2.

Fasten adapter plate in place, tighten capscrews to 50

to 75 ft-lbs [6.9 to 10.4 kg m] torque.

Install torque reaction

bar (3) into plate.

3.

Install gear drive (2) onto boring tool with 1/2 inch

square drive engaging boring tool and gear drive anchor arm

engaged over the torque reaction bar.

4.

Install drive adapter (12) into drill motor (1)and fasten

in place.

Engage adapter and motor onto gear drive.

5.

Being sure boring tool shaft is in maximum up position,

turn on drill motor.

Initial contact of tool bit with bore will be

intermittent and care should be exercised at start of cut.

While

unit is rotating, apply a slight downward pressure until

maximum depth bf bore is complete.

6.

Pull-up on drive shaft of boring tool (turning clockwise)

until drive shaft is in up position, then repeat procedure to be

sure of a true hole.

344

Back to Top