TM-5-3805-254-14-P-2 - Page 455 of 894

MOTOR TRUCK SERVICE MANUAL

FRAMES

Important

In addition to the specific recommendations given in

these paragraphs, always remember the following

general rules of welding “good housekeeping”.

1.

Surface areas and edges to be joined must be

clean and free of oil or grease.

2.

Always

avoid

craters,

notching,

and

undercutting.

3.

Peen new welds to relieve stresses caused by

shrinkage.

Positioning of Frame Reinforcements

Whenever

practical,

the

welding

of

frame

reinforcements should be confined to the web of the side

rail rather than the flanges.

This procedure provides the

strongest possible assembly.

Avoid at all times welds made square with the side

rail, either on webs or flanges.

When welds are made at

an angle of at least 30 degrees from square, there is less

possibility of setting up dangerous stress concentrations

in the rail.

Physical tests of the strength of various welds

have shown that a weld made at an angle of at least 30

degrees from the direc-tion of strain will retain the

original physical properties of the complete rail section.

Frame Straightening

Use of heat is not recommended when straightening

frames.

Heat weakens the structural characteristics of

frame members and all straightening should be done

cold.

Frame members (except aluminum) which are

bent or buckled sufficiently to show cracks or weakness

after straightening, should be replaced or reinforced.

Repair and Reinforcements

(Aluminum Alloy Frames)

The cutting and welding of aluminum alloy frames for

repair or reinforcement can be accomplished providing

correct procedures are followed and proper welding

equipment is utilized.

The use of heat for straightening

aluminum frame rails is not recommended.

BOLT SPECIFICATIONS AND TORQUES

While most IH frames are of riveted construction,

there are some frames which are assembled with bolts

and nuts.

Bolting,

though more costly does provide the field with a time

saving advantage when replacing cross-members or

frame attaching parts.

If bolting is used for altering or adding to the frame,

the following precautions must be observed.

NOTE: Bolts to be used for installing fifth wheels

must be 5/8” diameter high strength material such as I.

H.

type 8 (SAE grade 8) bolts.

Type 8 bolts can be

identified by the six radial lines on the head of the bolt.

Nuts must be of corresponding type.

The torque value for tightening these bolts is 220-

250 ft.

lbs.

and is based on new bolts and nuts

lubricated with engine oil.

If frame components are

aluminum, flat washers must be used next to the

aluminum whether under head, nut or both.

Proper tightening of bolts and nuts is most important,

since the strength of the joint depends on the maximum

clamping force between the members.

REPAIR AND REINFORCEMENTS

(Heat Treated Frames)

With the use of heat treated frame rails in

International vehicles, it becomes advisable to outline

some of the procedures to be followed whenever these

frames require repair.

Heat treated frame rails must not, of course, be

intermixed with non-heat treated rails.

If one side rail is

to be replaced, the new rail material must match the old

frame rail.

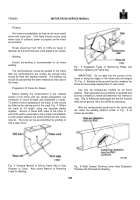

Preparation Of Frame For Repair

A good method to follow when repairing a cracked

frame where the crack is accessible from both sides is

as follows:

a.

Grind a V notch or groove extending along the full

length of the crack and slightly beyond each end of

the crack.

A heavy copper strip or “chill” should be

clamped to the rail side away from the groove to help

control the temperature and cooling rate.

See Fig.

7.

NOTE: Discarded short lengths of heavy copper

electrical bus bars make suitable chills.

451

Back to Top