TM-5-3805-254-14-P-2 - Page 457 of 894

MOTOR TRUCK SERVICE MANUAL

FRAMES

Welding

Position

Amperes

Voltage

Downhand

13 0/140

21/23

Overhead

130/140

21/23

Vertical Up

110/120

22/24

Use low hydrogen electrodes which have superior

crack resistance and notch toughness similar to AWS-E-

11018.

This type electrode should be stored in a

moisture-free container to avoid porosity during welding.

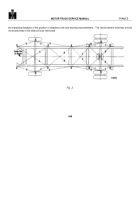

Fig.

9

Full Length Reinforcement

When heat treated frames are to be rein-forced over

a greater portion of their length, frame channel

reinforcements should be in-stalled using bolts.

Bolts of

high strength material conforming to SAE grade 5 or

better should be used.

The bolts and nuts should be

inspected periodically and kept tight, since the strength

of the reinforcement depends some-what on the

maximum clamping force between the members.

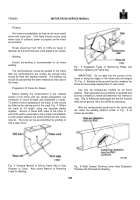

Drilling

The drilling of heat treated frame rails presents no

unusual difficulty.

Standard high speed drills of good

quality will serve provided they are sharpened properly

and not overheated during sharpening or use.

There

are, however, special high speed twist drills available

having special materials which will hold a cutting edge

longer.

These drills are expensive and require especially

rigid support, otherwise drill breakage will result.

When drilling heat treated rails, like in any other

drilling operation, sufficient pressure must be applied to

the drill bit to maintain continuous cutting.

The drill point

should frequently be drenched with cutting oil (soluble oil)

to help cool the drill.

Avoid letting a drill bit turn in the

work without cutting.

To do so will usually overheat and

ruin the drill.

The drill must be held steady during the drilling

operation.

Avoid wobble or change of drill angle during

the drilling operation.

Frame Straightening

When heat treated frame rails have been bent or

twisted, they should not be heated for straightening.

This

work should be done with the frame rails cold.

Heating

for straighten-ing purposes is likely to destroy the rail

temper in localized areas, which will bring about rail

failures.

453

Back to Top