TM-5-3805-254-14-P-2 - Page 727 of 894

TRUCK SERVICE MANUAL

TRANSMISSIONS

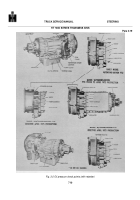

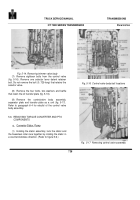

HT 700D SERIES TRANSMISSIONS

Para 4-4/4-5

4-4. CAREFUL HANDULING

During all rebuild procedures, parts and

subassemblies must be handled carefully to prevent

nicking, scratching and denting.

Parts which fit together

closely and have proper operating clearance can bind if

damaged. Parts which depend upon smooth surfaces for

sealing may leak if scratched. This is very important

concerning parts of the control valve body assembly

(valves, when dry, must move freely by their own weight).

Such parts should be carefully handled and protected

during removal, cleaning, inspection and installation as

well as being kept clean while in containers awaiting

installation.

4-5. CLEANING, INSPECTION

a. Dirt Causes Malfunction. All parts must be

clean to permit effective inspection.

At assembly, it is

very important that no dirt or foreign material be allowed

to enter the transmission.

Even minute part i c 1 e s can

cause the malfunction of close-fit parts, such as valves.

b. Cleaning Parts

(1) All the metallic parts of the transmission except

bearings and friction-faced clutch plates should

be cleaned thoroughly with volatile mineral spirits

or by the steam cleaning method. Do not use

caustic soda solution for steam cleaning. Use

only mineral spirits to clean friction-faced clutch

plates.

(2) Parts should be dried with compressed air.

Steam-cleaned

parts

should

be

oiled

immediately after drying.

(3) Clean oil passages by working a piece of soft

wire back and forth through the passages and

flushing with mineral spirits.

Dry the passages

with compressed air.

(4) Examine parts, especially oil passages, after

cleaning, to make certain they are entirely clean.

Reclean them if necessary.

c. Cleaning Bearings

(1) Bearings that have been in service should be

thoroughly washed in volatile mineral spirits.

(2) If the bearings a r e particularly dirty or filled with

hardened grease, soak them in the spirits before

trying to clean them.

(3) Before inspection, oil the bearings with the same

type of oil that will be used in the transmission.

Never dry bearings with compressed air. Do not spin

bearings while they are not lubricated.

d. Keeping Bearings Clean. Since the presence

of dirt or grit in ball bearings is usually responsible for

bearing failures, it is important to keep bearings clean

during removal and installation. Observance of the

following rules will do much to insure maximum bearing

life.

(1) Do not remove the wrapper from new bearings

until ready to install them.

(2) Do not remove the grease in which new bearings

are packed.

(3) Do not lay bearings on a dirty bench; place them

on clean, lint-free paper.

(4) If assembly is not to be completed at once, wrap

or cover the exposed bearings with clean paper

or lint-free cloth to keep out dust.

e. Inspecting Cast Parts, Machined Surfaces.

(1) Inspect bores for wear, scratches, grooves and

dirt. Remove scratches and burs with crocus

cloth. Remove foreign matter.

Replace parts

that are deeply scratched or grooved.

(2) Inspect all oil passages for obstructions. If an

obstruction is found, remove it with compressed

air, or by working a soft wire back and forth

through the passage and flushing it out with

cleaning solvent.

(3) Inspect

mounting

faces

for

nicks,

burs,

scratches,

and

foreign

matter.

Remove

720

Back to Top