TM-5-3805-274-13-P - Page 106 of 364

Field Preventive Maintenance Checks and Services (PMCS) for M917 Dump Truck.

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT NOT

READY/AVAILABLE

IF:

1.

Quarterly or

250 hrs.

Side marker lights

(Figure 1, Item 1)

and rear marker

lights

(Figure 1, Item 2).

1. Inspect all lamps for proper operation.

2. Inspect lens and housings for damage.

3. Replace marker lights as required. Refer

to WP 0023.

4. Replace lamps as required. Refer to

WP 0024.

1

2

1

2

Figure 1. Side Marker Lights and Rear Marker Lights.

2.

Quarterly or

250 hrs.

Hydraulic reservoir

(Figure 2, Item 1),

upper sight glass

(Figure 2, Item 2),

and lower sight

glass

(Figure 2, Item 3).

1. Inspect reservoir for leaks or damage.

2. Check fluid level through hole in front of

dump bed. Add fluid if not visible in

upper sight glass.

3. Raise dump bed to maximum height and

check lower sight glass for fluid. Add

fluid until fluid is visible in sight glass.

Class III leaks are

evident.

1

2

3

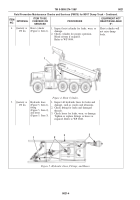

Figure 2. Hydraulic Reservoir, Upper Sight Glass, and Lower Sight Glass.

TM 5-3805-274-13&P

0021

0021-2

Back to Top