TM-5-3895-371-24-P - Page 212 of 330

TM 5-3895-371-24 & P

(7)

Examine wear plate (15, fig. 3-60). Circular patterns burnished on the surface of the

cam plate are normal, If the circular patterns on the wear plate are extensive and can be felt with the

fingernail or if angular scratches are evident, the plate must be discarded. (Refer to fig. 3-79.) Install

new dowel pin (9, fig. 3-60), if previously removed, by tapping in with a light weight hammer.

TA 075952

Figure 3-79. Inspecting Cam Wear Plate.

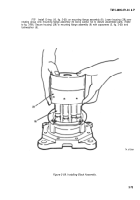

(8)

Match up dowel pin (9) with hole in wear plate (15) and seat plate (17). (Refer to fig.

3-80.) Check for proper seating by pushing down on first one edge then the other in a rocking motion.

If any looseness is felt, remove wear plate (15, fig. 3-60) and clean the cam assembly and wear plate to

remove any foreign particles from beneath the wear plate (15). Reposition wear plate (15) and again

check for proper seating. If wear plate (15) still does not seat properly, check wear plate (15) for flat-

ness and replace if necessary.

Figure 3-80. Installing Cam Wear Plate.

TA 075963

3-67

Back to Top