TM-5-3895-372-20 - Page 350 of 694

TM 5-3895-372-20

AGGREGATE SUPPLY SYSTEM.

7-15. CONVEYOR BELT AND BELT LACER REPAIR (Continued).

LOCATION/ITEM

ACTION

REMARKS

REPAIR (Continued).

NOTE

For replacement of belt sections, count back three crossbars (10) from the damaged section at each end.

2.

Rubber belt (9).

Cut belt between the third

and fourth crossbars (10)

at each end.

3.

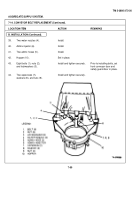

Bolts (11) and

Unscrew and remove the

If necessary, shear off nuts

nuts (8).

old rubber belt (9) from

(8) with a chisel and hammer.

the crossbars (10).

4.

Chain (2).

Connect the chain and secure

If replacing belt lacer (7)

with two pins (4).

only.

NOTE

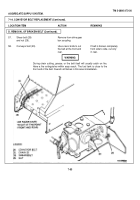

There cannot be any crossbars at the lacer/lacers. If necessary, remove crossbars.

The chain will be left the same length.

5.

Rubber belt (9).

a. Stretch the area to be

repaired.

b. Lay damaged rubber belt

(9) on top of new rubber

belt and cut to same length.

c. Clamp one end of the new

rubber belt (9) onto the

first crossbar (10).

NOTE

Be sure that 0.56 in. (14.3 mm) of the rubber belt (9) is extending beyond the centerline of the second roller (3). The

thicker coating of rubber should be on the conveying side of the rubber belt.

d.Using the crossbar (10)

as a jig, drill 0.28 (7.1

mm) holes in the new

rubber belt (9).

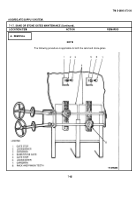

6.

Bolts (11) and

Install thru new rubber belt

nuts (8).

(9) and crossbar (10). Tighten

bolts until flat head is flush

with its surface.

7-58

Back to Top