TM-5-5420-202-20-2 - Page 29 of 734

TM 5-5420-202-20-2

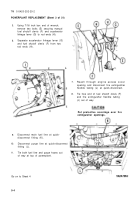

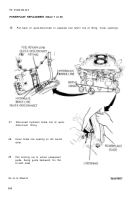

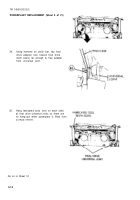

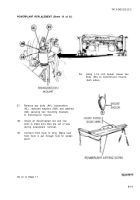

POWERPLANT REPLACEMENT (Sheet 1 of 21)

PROCEDURE INDEX

PROCEDURE

PAGE

Removal

5-2

Installation

5-14

9/16 in. socket with 1/2 in. drive

TOOLS:

7/16 in. socket with 1/2 in. drive

Ratchet with 1/2 in. drive

Flat-tip screwdriver

Long round nose pliers

7/16 in. combination box and open end wrench

11/16 in. combination box and open end wrench

7/8 in. combination box and open end wrench

7/8 in. crowfoot with 3/8 in drive

Diagonal cutting pliers

3/4 in. socket with 1/2 in. drive

Spanner wrench

Pinch bar

5 in. extension with 1/2 in. drive

1-1/2 in. socket with 3/4 in. drive

Ratchet with 3/4 in. drive

Universal joint with 1/2 in. drive

Hammer

Torque wrench with 3/8 in. drive (0-600 lb-in) (0-68 NŽm)

Torque wrench with 1/2 in. drive (0-175 lb-ft) (0-237 NŽm)

Torque wrench with 3/4 in. drive (0-600 lb-ft) (0-813 N m)

Adjustable wrench

5 ton hoist capable of lifting powerplant 12 ft. high

SPECIAL TOOLS

Final drive guide shields (Fig. F-1, Appendix F) (2 required)

Final drive adapter hook-up tool (Fig. F-4, Appendix F)

Engine and transmission sling (Item 32, Chapter 3, Section

I)

SUPPLIES:

Covers for fire extinguisher flexible tubing

Covers for hydraulic brake line openings

Covers for fuel lines openings

Covers for air cleaner hoses and outlets

Grease (Item 37, Appendix D)

Lockwire (Item 61, Appendix D)

Light rope (or heavy masking tape)

Cotter pins

Wooden blocks 12 in. x 12 in.

Lockwashers

PERSONNEL: Three

REFERENCE:

TM 5-5420-202-10

NOTE

Use suitable container to catch fuel whenever any fuel

Iine or connection is loosened or disconnected. Use cloth

to wipe any spillage. Discard cloth and drained fuel in

Go on to Sheet 2

accordance with local procedures.

5-2

Change 3

Back to Top