TM-9-2320-260-10 - Page 129 of 411

2-70.14

Change 4

TM 9-2320-260-10

Table 2-2. Preventive Maintenance Checks and Services (Cont’d).

ITEM

NO.

INTERVAL

ITEM TO

CHECK/

SERVICE

CREWMEMBER

PROCEDURE

NOT FULLY

MISSION

CAPABLE IF:

LOCATION

DRIVER

70

Weekly

Wrecker

a.

Check PTOs, drive shafts, hydraulic Any class III leak

Crane

pumps, and control valves for damage,

is evident or

leakage, and security of mounting.

damage is evident.

b.

Check hydraulic tank oil level.

DRIVER

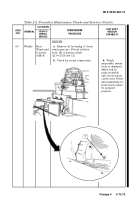

71

Weekly

D i ff e r e n t i a l s Visually inspect rear differentials for

Any class III leak

oil leaks (para. 2-10).

is evident.

DRIVER

72

Weekly

Transfer

Check all transfer case and transmission

Any loose or

Case and

bolts for looseness.

missing bolts.

Tr a n s m i s -

s i o n Bolts

DRIVER

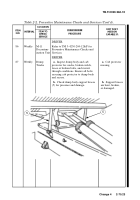

73

Weekly

Underbody

Visually inspect frame side rails, cross-

Any side rail or

Frame

members, and underbody supports for

crossmember is

broken bolts, cracks, breaks, broken

obviously broken;

welds, rivets, and rusted-through

any weld, bolt, or

conditions.

rivet broken or

rusted through.

CAUTION

• Before opening reservoir, ensure

area around reservoir cap is

clean. Do not allow dirt, dust, or

water to enter reservoir. Failure

to do so will cause damage to

internal components.

• Do not overfill hydraulic oil

reservoir. Damage to internal

components will result.

Back to Top