TM-9-2320-260-10 - Page 121 of 411

2-70.6

Change 4

TM 9-2320-260-10

Table 2-2. Preventive Maintenance Checks and Services (Cont’d).

ITEM

NO.

INTERVAL

ITEM TO

CHECK/

SERVICE

CREWMEMBER

PROCEDURE

NOT FULLY

MISSION

CAPABLE IF:

LOCATION

SPECIALBODY EQUIPMENT

DRIVER

58

After

Hydraulic

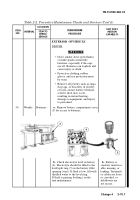

Check hydraulic reservoir level by

Any class III leak

Tank Oil

removing filler cap (1) and pulling out

is evident, or cap

Level

dipstick (2). Oil level should be at the

missing.

third mark from top of gauge, with

hydraulic components in traveling

position. If oil level is low, fill to top

line (LO 9-2320-260-12). After check,

ensure filter cap (1) is tight.

CAUTION

Before opening reservoir, ensure

area around reservoir filler cap is

clean. Do not allow dirt, dust, or

water to enter reservoir. Failure to

do this will cause damage to

internal components.

NOTE

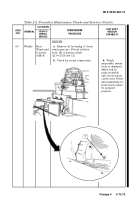

• Hydraulic tank oil level reference

applies only to M813/M813A1,

M814, and M817 models.

• If vehicle has positive locking

device, inspect the attaching

hardware for loose or missing

bolts prior to stowing in up

position. If loose or missing, do

not stow bed in up position.

• Ensure bed is in travel mode

before checking oil level.

1

2

Back to Top