TM-9-2320-260-10 - Page 115 of 411

2-70

Change 4

TM 9-2320-260-10

Table 2-2. Preventive Maintenance Checks and Services (Cont’d).

ITEM

NO.

INTERVAL

ITEM TO

CHECK/

SERVICE

CREWMEMBER

PROCEDURE

NOT FULLY

MISSION

CAPABLE IF:

LOCATION

DRIVER

49

After

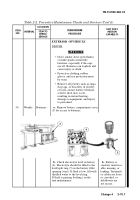

Hydraulic

a.

Check PTO, drive shaft, hydraulic

a.

Any class III

Hoist

pump, and control valve for damage,

leak is evident.

leakage, and security of mounting.

b.

Inspect cylinders (1) for damage,

b.

Any class III

leakage, and secure mounting to

leak is evident.

subframe.

c.

Check roller arm assembly (2) for

c.

Any evidence

cracks, breaks, damage, and security

of cracks, breaks,

of mountings.

damage, or loose

mountings.

d.

Stop engine (para. 2-16).

WARNING

Never perform PMCS checks under

raised dump body unless safety

braces are properly positioned. If

dump body suddenly lowers, serious

injury or death will result.

NOTE

Hydraulic hoist reference applies

only to M817 model vehicles.

1

2

Back to Top