TM-9-2320-260-34-1 - Page 118 of 657

TM 9-2320-260-34-1

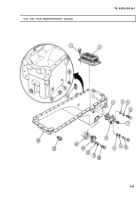

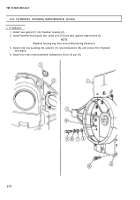

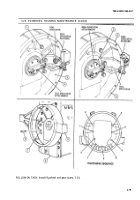

3-21. FLYWHEEL AND GEAR REPLACEMENT

THIS TASK COVERS:

a. Flywheel Removal

c. Ring Gear Installation

b. Ring Gear Removal

d. Flywheel Installation

INITIAL SETUP

APPLICABLE MODELS

All

SPECIAL TOOLS

Engine barring tool (Appendix B, Item 66)

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

Soft-head hammer (Appendix B, Item 47)

Torque wrench, 1/2-in. dr.

(Appendix B, Item 3)

Two dowel pins (Appendix E, Figure E-1)

Two puller screws (Appendix C, Item 41)

MATERIALS/PARTS

Safety wire (Appendix D, Item 373)

Tempilstik crayon (Appendix C, Item 10)

REFERENCES (TM)

TM 9-2320-260-10

TM 9-2320-260-34P-1

EQUIPMENT CONDITION

• Parking brake set (TM 9-2320-260-10).

• Transmission removed (para. 8-4).

• Clutch and pressure plate removed (para. 4-2).

GENERAL SAFETY INSTRUCTIONS

• Wear gloves at all times when handling heated

parts.

• Flywheel is heavy; use caution when removing.

a. Flywheel Removal

1. Remove safety wire (4) from screws (5). Discard safety wire (4).

2. Remove two screws (5) and washers (6) from flywheel (7) and install two dowel pins.

3. Remove four screws (5) and washers (6) from flywheel (7).

WARNING

Flywheel is heavy. Use caution when removing from flywheel

housing. Failure to do so may cause injury to personnel.

NOTE

Assistant will help with step 4.

4. Install two puller screws (3) on flywheel (7). Tighten jackscrews (3) alternately and remove

flywheel (7) from crankshaft (1).

5. Remove puller screws (3) from flywheel (7).

6. Remove dowel pins from crankshaft (1).

b. Ring Gear Removal

WARNING

Wear gloves at all times when handling heated parts. Failure to do

so may cause injury to personnel.

CAUTION

Do not heat ring gear above 600°F (316°C). Overheating of ring

gear may cause damage.

3-66

Back to Top