TM-9-2320-260-34-1 - Page 348 of 657

TM 9-2320-260-34-1

5-11. FLOW TEST

THIS TASK COVERS:

a. Test Stand Setup

c. Fuel Delivery Adjustment and Measurement

b. Check Ball Seating Test

INITIAL SETUP

APPLICABLE MODELS

All

SPECIAL TOOLS

Adjusting wrench (Appendix B, Item 154

Locknut wrench (Appendix B, Item 25)

TEST EQUIPMENT

Injector test stand (Appendix B, Item 26)

Test stand link (Appendix B, Item 27)

MATERIALS/PARTS

Retaining ring (Appendix D, Item 342)

Screen (Appendix D, Item 377)

MATERIALS/PARTS (Contd)

Gasket (Appendix D, Item 117)

Orifice plug (Appendix D, Item 321)

Diesel fuel (Appendix C, Item 13)

REFERENCES (TM)

TM 9-2320-260-10

TM 9-2320-260-34P-1

EQUIPMENT CONDITION

l Parking brake set (TM 9-2320-260-10).

l Fuel injectors removed (para. 5-6).

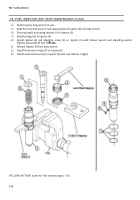

a. Test Stand Setup

1.

2.

3.

4.

5.

6.

7.

8.

9.

Remove screen retainer (1) and screen (2) from injector inlet port (3). Discard retaining ring (1) and

screen (2).

NOTE

Perform step 2 for non-top stop injector.

Remove plunger (5) and plunger spring (6) from injector (4).

NOTE

Perform steps 3 and 4 for top stop injector.

Using adjusting wrench and locknut wrench, remove locknut (7) and adjusting screw (8) from

injector (4).

Remove plunger (5), spring retainer (9), and plunger spring (6) from injector (4).

Place plunger (5) in injector (4).

Lubricate inside of burnishing tool adapter (10) with diesel fuel.

Position injector (4) in burnishing tool adapter (10) so injector inlet port (3) and adapter inlet

holes (11) aline.

Install locating screw (12) in burnishing tool adapter (10).

Connect pressure line adapter (13) to burnishing tool adapter (10).

5-28

Back to Top