TM-9-2320-260-34-2 - Page 503 of 863

TM 9-2320-260-34-2

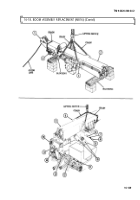

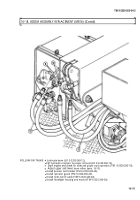

16-18. BOOM ASSEMBLY REPLACEMENT (M816)

THIS TASK COVERS:

a. Removal

b. Installation

INITIALSETUP

APPLICABLE MODELS

M816

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

3/4-in. torque wrench (Appendix B, Item 2)

1-5/8-in. socket, 3/4-in. dr.

(Appendix B, Item 102)

1-718-in. socket, 3/4-in. dr.

(Appendix B, Item 135)

Torque multiplier

Blocking

Two chains

Lifting device

Guide lines

MATERIALS/PARTS

Two lockwashers (Appendix D. Item 223)

Locknut (Appendix D, Item 202)

GM grease (Appendix C, Item 14)

Antiseize tape (Appendix C, Item 50)

Cap and plug set (Appendix C, Item 6)

PERSONNEL REQUIRED

Two

REFERENCES (TM)

LO 9-2320-260-12

TM 9-2320-260-10

TM 9-2320-260-20

TM 9-2320-260-34P-2

EQUIPMENT CONDITION

●

Hydraulic reservoir drained (LO 9-2320-260-12).

●

Hoist winch cable removed (TM 9-2320-260-20).

Operator guard removed (TM 9-2320-260-20).

●

Pioneer tool bracket removed (TM 9-2320-260-20).

●

Floodlight housing and mount removed

(TM 9-2320-260-20).

GENERAL SAFETY INSTRUCTIONS

●

All

personnel must stand clear during lifting

operations.

●

Keep hands clear during removal and installation

of boom.

●

Ensure lifting capacity is greater than weight of

boom assembly.

a. Removal

●

●

WARNING

All personnel must stand clear during lifting operations.

A swinging or shifting load may cause injury to personnel.

Ensure lifting capacity is greater than weight of boom assembly.

Failure to do so may result in injury to personnel or damage to

equipment.

NOTE

Two assistants will help with this procedure.

1. Install chain on boom (1) and attach to lifting device.

2. Wrap second chain around lower boom roller (4) and inner boom (3) to hold inner boom (3)

in position.

3. Raise boom (1) to remove weight from shipper braces (2).

4. Remove two safety pins (5) and shipper braces (2) from boom (1).

5. Remove two safety pins (6), pins (8), and shipper braces (2) from brackets (7).

16-104

Back to Top