TM-9-2320-272-10 - Page 199 of 481

2-98

Change 2

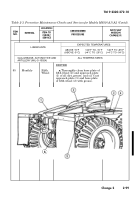

Table 2-3. Preventive Maintenance Checks and Services for Models M939/A1/A2 (Contd).

ITEM

NO.

INTERVAL

ITEM TO

CHECK/

SERVICE

NOT FULLY

MISSION

CAPABLE IF:

TM 9-2320-272-10

LOCATION

CREWMEMBER

PROCEDURE

84

84a

Monthly

Monthly

Frame

Inspection

Axle

Breather

DRIVER

a.

Check the chassis for loose or

missing screws (3) and rivets (4)

securing fifth wheel (2) to side

rails (5), and side rails (5) to vehi-

cle (TB 9-2300-247-40).

b.

Using a .001–inch–thick feeler

gauge, check for space between

rivet head and the riveted frame

members. Penetration of the feeler

gauge between the rivet head and

the riveted member is reason to

suspect that the riveted connection

and/or rivet should be replaced.

c.

Thoroughly clean rivet and

riveted connection of all dirt,

grease, and oil. Using an oil can,

apply lubricating oil around the

suspect rivet and riveted connec-

tion. Allow approximately 10 to 20

seconds for the oil to penetrate.

Wipe rivet and riveted connection

free of oil. Tap rivet with an eight-

pound hammer. Any indication of

oil around the rivet indicates a

loose rivet. Notify unit mainte-

nance to replace all loose rivets.

Check all riveted connections for

signs of movement, such as bare or

shiny spots, or other indications of

movement between rivet and fram-

ing member. If movement is indi-

cated, rivet and connection are

loose.

CAUTION

Axle breathers must be cleaned

before servicing to prevent dam-

age to axle from contamination.

Remove, clean, and lubricate

axle breathers every 1000 miles

(1600 km) or monthly, which-

ever occurs first.

Check all axle breathers (6) for

damage or dirt.

b.

Loose or

missing rivets.

c.

Loose or

missing rivets.

Back to Top