TM-9-2320-272-23-1 - Page 241 of 1313

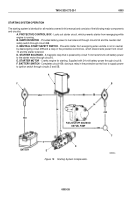

AIR PRESSURE SUPPLY SYSTEM OPERATION

A constant air pressure supply is developed by the compressor which is regulated by the governor to maintain 90

to 120 psi (621 to 827 kPa) for the airbrake system. Moisture within the system is controlled through the use of either

the alcohol evaporator or air dryer. The major components of the system are:

A. AIR DRYER

- Installed in supply line to wet tank and removes moisture from inlet air to wet tank

(M939/A1 air dryer kit installed only).

B. AIR COMPRESSOR

- Draws in air from the intake manifold and forces it into brake system and wet

tank

reservoir.

C. SAFETY VALVE

- Located at inlet side of wet reservoir, it prevents pressure buildup by releasing air

pressure exceeding 150 psi (1,034 kPa) when the governor fails to regulate air supplied by the compressor.

D. WET TANK RESERVOIR

- Performs two functions:

•

Traps water in air reservoir to protect other air systems from freezing or corroding.

•

Stores reserve air supply enabling operator to make normal stops when engine stalls or

compressor

fails.

E. PRESSURE PROTECTION VALVE

- Performs two functions:

•

Allows air pressure to build to 60 to 65 psi (414 to 448 kPa) before supplying air to auxiliary air-

powered equipment.

•

Closes off auxiliary air system from other systems if an accessory fails and prevents loss of air from

secondary reservoir.

F. WET TANK RESERVOIR DRAIN VALVE

- Provides a drain for moisture and air from reservoir.

G. AIR DRYER

- Removes moisture from inlet air to wet tank (M939A2 only).

H. GOVERNOR

- Trips valve inside compressor to regulate flow of air to the system. When pressure builds

to 120 to 127 psi (827 to 876 kPa), the governor will close valve.

TM 9-2320-272-23-1

0003

0003-36

Back to Top