TM-9-2320-272-23-1 - Page 243 of 1313

AIR PRESSURE SUPPLY SYSTEM OPERATION - Continued

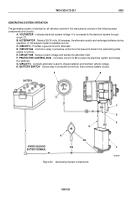

The constant air pressure supply is distributed to the primary service airbrake system and secondary airbrake system

through a shutoff and check valve. Air pressure can either be fed from or supplied to another vehicle through the

emergency couplings.

A. FRONT EMERGENCY COUPLING

- When vehicle is being towed, coupling receives compressed air

from towing vehicle's brake system to charge its own brake system.

B. PRIMARY AIR RESERVOIR

- Stores sufficient air pressure to allow operator to make normal brake

applications if system pressure fails or engine stalls.

C. PRIMARY FEED CUTOFF

- Manually-operated valve used to isolate pressure leaks in primary air system

from draining wet tank (TM 9-2320-272-10).

D. PRIMARY AIR RESERVOIR CHECKVALVE

- Prevents backflow of air from primary tank if wet system

develops a leak.

E. SECONDARY FEED CUTOFF

- Manually-operated valve used to isolate pressure leaks in secondary

air system from draining wet tank (TM 9-2320-272-10).

F. SECONDARY AIR RESERVOIR CHECKVALVE

- Prevents backflow of air from secondary tank if wet

system develops a leak.

G. REAR EMERGENCY COUPLING

- When towing another vehicle, coupling allows pressurized air from

wet tank to charge towed vehicle's wet tank.

H. SECONDARY AIR RESERVOIR

- Stores enough air pressure in case constant pressure system fails or

engine stalls. The operator can make normal brake application before running out of air.

I. PRESSURE PROTECTION VALVE

- Performs two functions:

•

Allows air pressure to build to 60 to 65 psi (414 to 444 kPa) before supplying air to auxiliary air-

powered equipment.

•

Closes off auxiliary air system from other systems if an accessory fails and prevents loss of air from

secondary reservoir.

TM 9-2320-272-23-1

0003

0003-38

Back to Top