TM-9-2320-272-23-3 - Page 231 of 1469

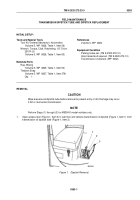

OIL FILTER INSTALLATION - Continued

CAUTION

Do not use gasket sealing compound when installing oil pan gasket; oil leakage will result. If

necessary, oil or light grease coating may be used to hold oil pan gasket in position

during

installation.

5.

Install oil pan gasket (Figure 4, Item 2) and oil pan (Figure 4, Item 4) on transmission (Figure 4, Item 1) with

21 screws (Figure 4, Item 3).

6.

Tighten 21 screws (Figure 4, Item 3) to 10 to 15 lb-ft (14 to 20 N·m) in sequence shown in Figure 4.

NOTE

Due to gasket compression, torque values will be lost and screws must be retightened.

7.

After oil pan gasket (Figure 4, Item 2) is seated, loosen and retighten screws (Figure 4, Item 3) 5 lb-ft (7

N·m)

in sequence shown.

8.

Install dipstick tube (Figure 4, Item 5) on transmission (Figure 4, Item 1) with washer (Figure 4, Item 10), clamp

(Figure 4, Item 11), and screw (Figure 4, Item 12).

9.

Install dipstick tube (Figure 4, Item 5) in oil pan port (Figure 4, Item 9) with flare nut (Figure 4, Item 8). Tighten

flare nut 10 to 25 lb-ft (14 to 34 N·m).

10.

Install tiedown strap (Figure 4, Item 6) on dipstick tube (Figure 4, Item 5) and tube (Figure 4, Item 7).

TM 9-2320-272-23-3

0362

0362-8

Back to Top