TM-9-2320-272-23-4 - Page 1063 of 1393

INSTALLATION

1.

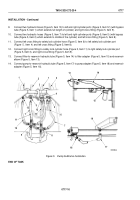

Attach two utility chains (Figure 4, Item 3) to subframe (Figure 4, Item 1).

2.

Attach lifting device (Figure 4, Item 2) to center of two utility chains (Figure 4, Item 3) and remove slack from

utility chain.

3.

Connect two guide lines (Figure 4, Item 10) to front and rear of subframe (Figure 4, Item 1).

WARNING

All personnel must stand clear during lifting operations. A snapped chain, or shifting or

swinging load, may result in injury to personnel. Failure to comply may result in injury or death

to personnel.

NOTE

Mechanic will handle one guide line and direct hoisting operation. Assistant will handle other

guide line. Second assistant will operate lifting device.

4.

Lift subframe (Figure 4, Item 1) clear of two shop stands (Figure 4, Item 9) and lower onto frame

(Figure 4, Item 8).

5.

Using drift pin, align holes in brackets (Figure 4, Items 5 and 14).

6.

Install two rear holddown brackets (Figure 4, Item 5) on frame (Figure 4, Item 8) with eight screws

(Figure

4,

Item

7) and locknuts (Figure 4, Item 6).

7.

Remove guide lines (Figure 4, Item 10), lifting device (Figure 4, Item 2), and utility chains (Figure 4, Item 3)

from subframe (Figure 4, Item 1).

8.

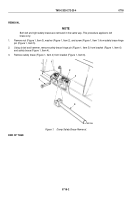

Install two front holddown brackets (Figure 4, Item 14) on frame (Figure 4, Item 8) with lower half-keeper

(Figure 4, Item 15), spring (Figure 4, Item 16), upper half-keeper (Figure 4, Item 17), screw

(Figure 4, Item 18), washer (Figure 4, Item 13), slotted nut (Figure 4, Item 12), and cotter pin

(Figure 4, Item 11).

TM 9-2320-272-23-4

0717

0717-8

Back to Top