TM-9-2320-272-24-2 - Page 808 of 991

TM 9-2320-272-24-2

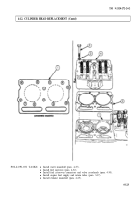

4-14. CRANKSHAFT VIBRATION AND DAMPER REPLACEMENT

THIS TASK COVERS:

a. Runout and Wobble Check

c. Inspection

b. Removal

d. Installation

INITIAL SETUP:

APPLICABLE MODELS

M939/A1

SPECIAL TOOLS

Barring tool (Appendix E, Item 8)

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

Dial indicator (Appendix E, Item 36)

MATERIALS/PARTS

Six lockwashers (Appendix D. Item 350)

REFERENCES (TM)

TM 9-2320-272-24P

EQUIPMENT CONDITION

l

Radiator fan shroud removed (para. 3-63).

•

Radiator fan blade removed (para. 3-72).

l

Alternator belts removed (para. 3-78).

a. Runout and Wobble Check

NOTE

Perform steps 1 through 3 to check for runout.

1.

Mount dial indicator and holding fixture on front gearcase cover (2).

2.

Position dial arm on vibration damper (1) at surface (3) and zero-dial indicator.

3.

Using barring tool, rotate vibration damper (1) and take reading. If reading exceeds 0.025 in.

(0.63 mm), replace vibration damper (1).

NOTE

l

Perform steps 4 through 6 to check for runout.

l

Crankshaft must be kept at front or rear limit of thrust while

checking vibration damper for wobble.

4.

Using mounted dial indicator, position dial arm on vibration damper (1) at surface (4) and zero-dial

indicator.

5.

Using barring tool, rotate vibration damper (1) and take reading. If reading exceeds 0.030 in.

(0.76 mm), replace vibration damper (1).

6.

Remove dial indicator and fixture.

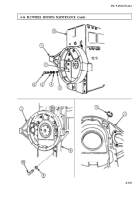

Remove six screws (5), lockwashers (6), and vibration damper (1) from crankshaft flange (7). Discard

lockwashers (6).

4-126

Back to Top